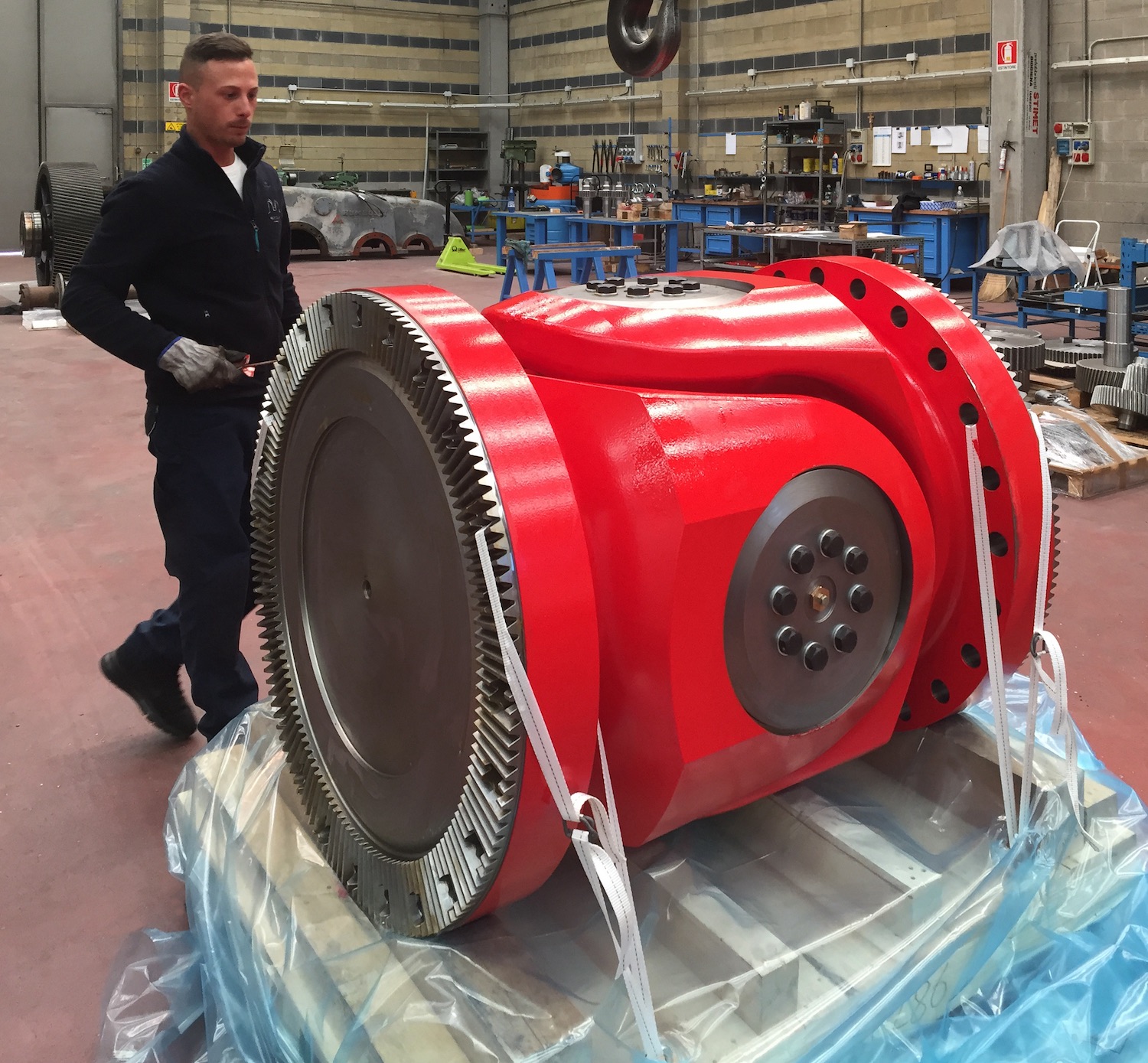

ABS custom designs and manufactures two Cardan Knuckles for the MC3 reversing mill of the hot rolling mill with higher strength, higher load capacity, and simplified maintenance parameters.

ABS New Cardan Knuckles doubles the output of the production of the original ones at Ternium’s Churubusco plant

See the project on ABS Newsletter pdf

See the project on ABS Newsletter pdf (spanish version)

-

These are the largest Cardan Knuckles installed in the Americas

-

More than 8 million tons of steel produced and still running!

-

5 million Nm of working torque

ABS and Ternium: a solid and trusting relationship

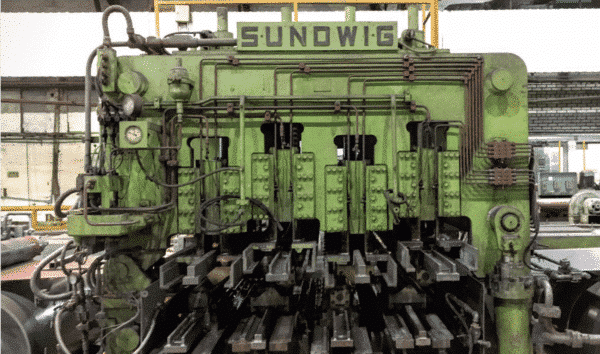

For some years now, Ternium México, a leading company in the steel industry in Mexico and LATAM, has been making important improvements in the Churubusco Hot Mill to manufacture Dual Phase steel. This special steel, mainly used in the automotive industry, has an excellent balance between strength and ductility.

ABS’s relationship with Ternium Mexico has been thriving since 2000. Since then, we have been collaborating regularly on different projects, particularly in the development of mechanical components for the Cardan shafts of the reversible mill 3 (MC3) of the hot rolling mill at its plant in Churubusco.

First, ABS designed the journal cross and bearing assemblies, then constructed the entire Cardan Knuckles. In 2023 the couplings from the node to the roller, which ABS designed and ACB Bearings and MGS Gears fabricated, will be dispensed, and installed.

A technical challenge within the reach of very few!

Cardan Knuckles are subjected to very demanding working conditions: high torque, high impact loads due to the rolling process, change of direction of rotation, and high temperatures. The original cardan Knuckles of Ternium’s reversible mill (MC3) had begun to show signs of wear and demanded a solution that would offer greater resistance, increase their load capacity, and facilitate maintenance tasks.

Achieving compliance with the technical requirements through a design that integrated the cardan knuckles in the system without altering its measurements or modifying the mounting characteristics posed a significant technical challenge.

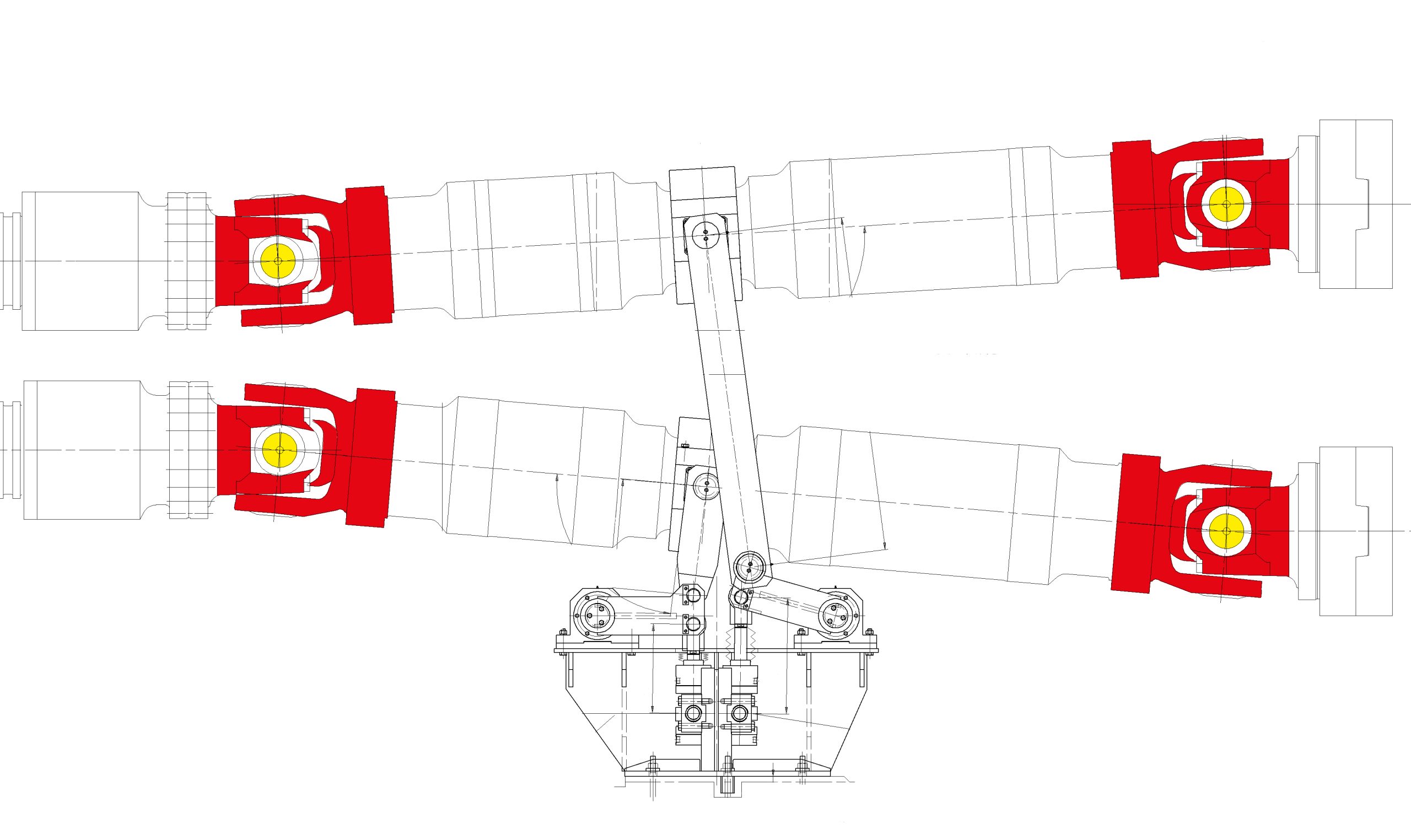

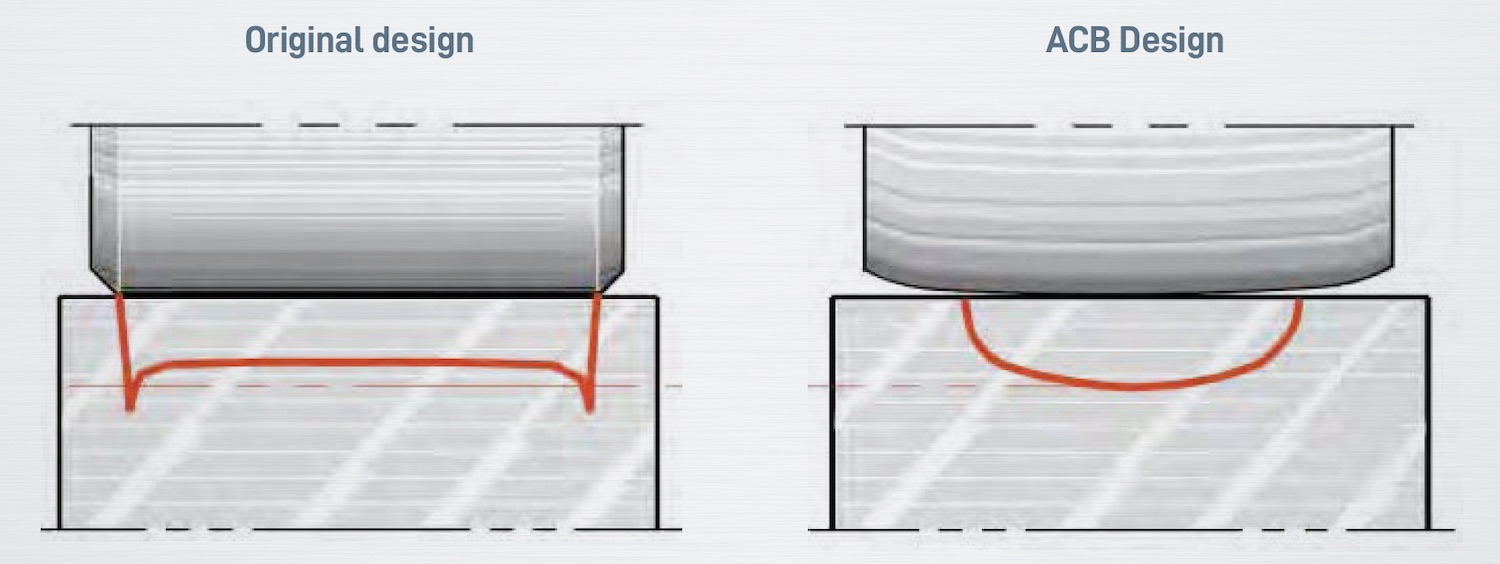

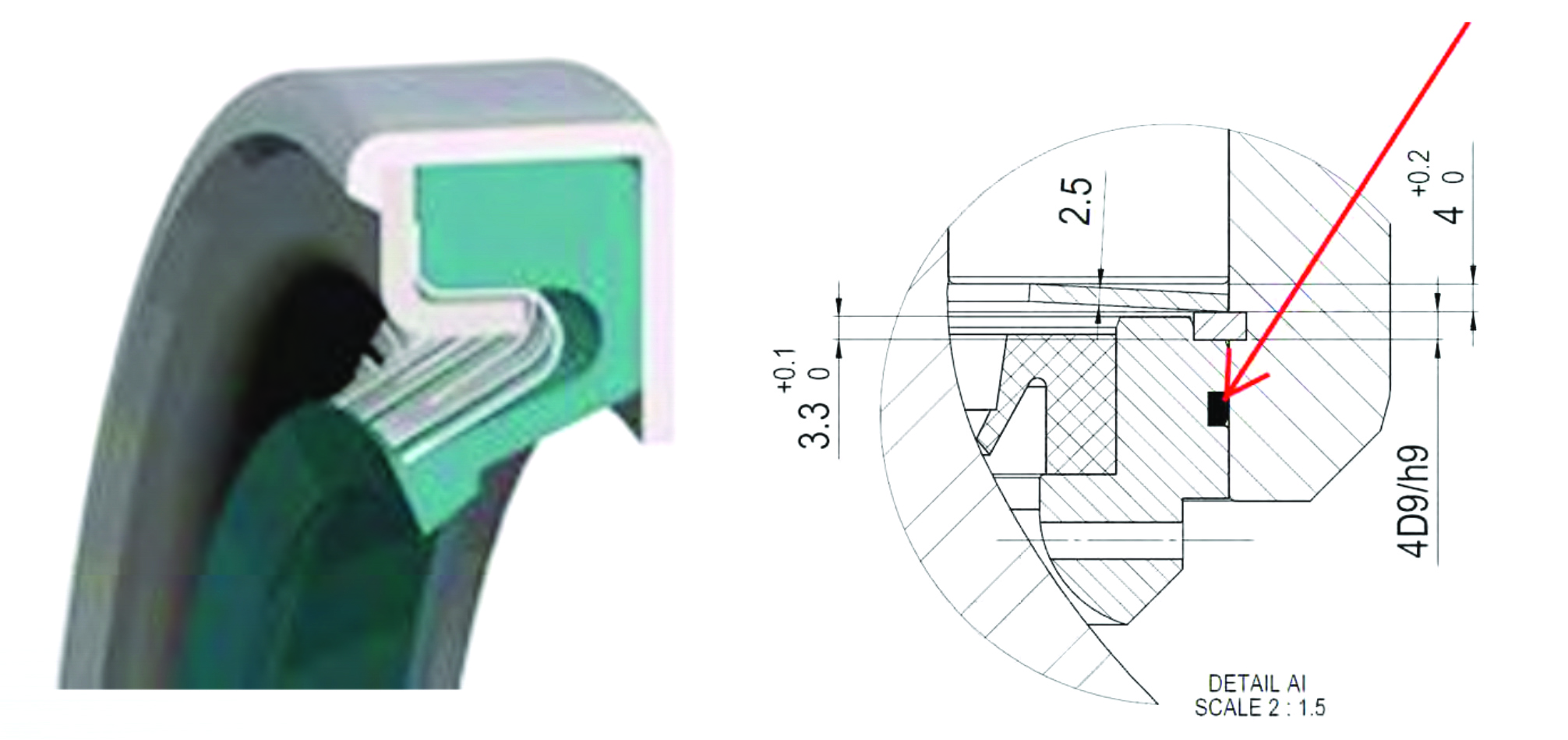

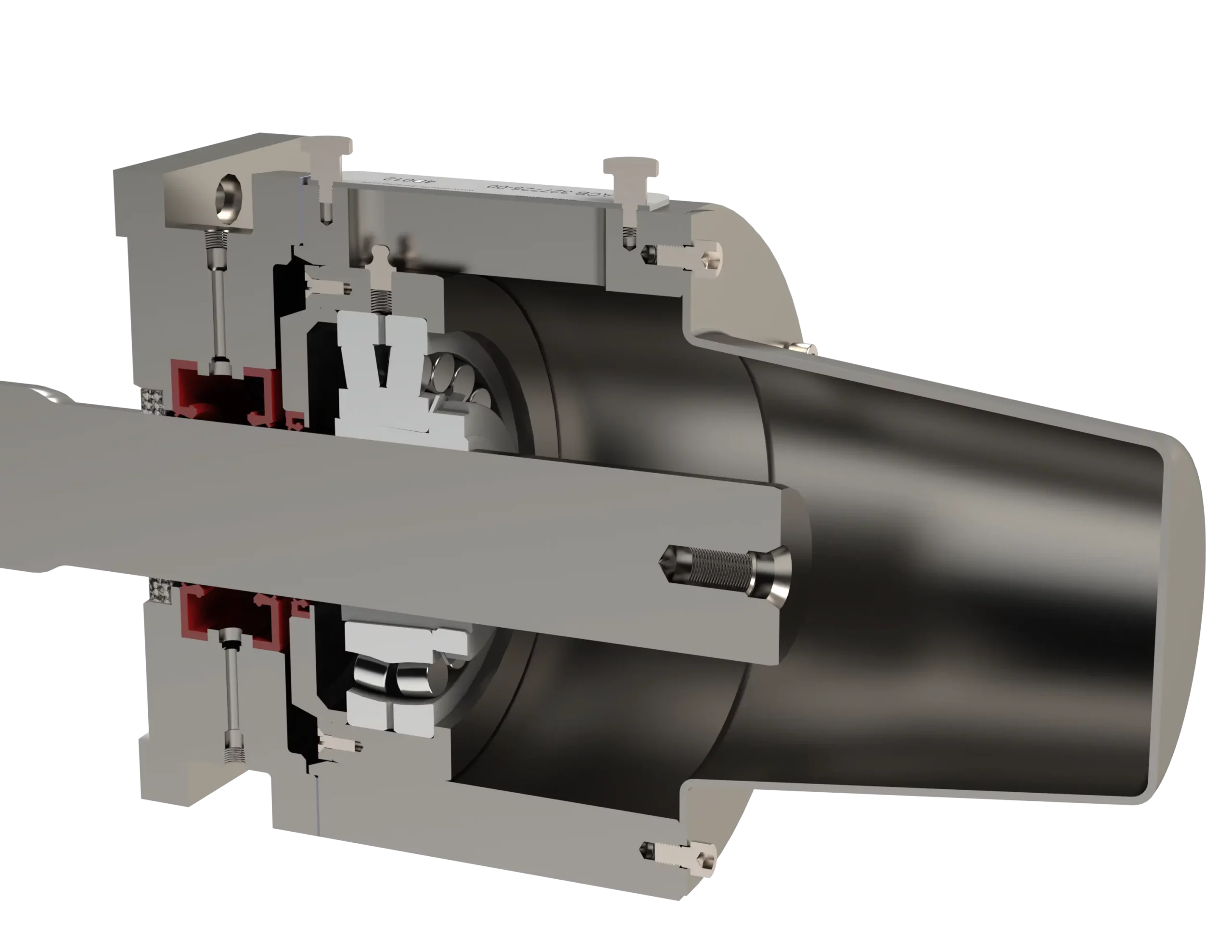

Drawing of the new ABS design, with components from ACB and MGS Gears, resulting in new technical properties that considerably surpassed those of the original component.

A “dream team” for the new design!

The engineering of ABS, the reliability of ACB, and the precision of MGS Gears

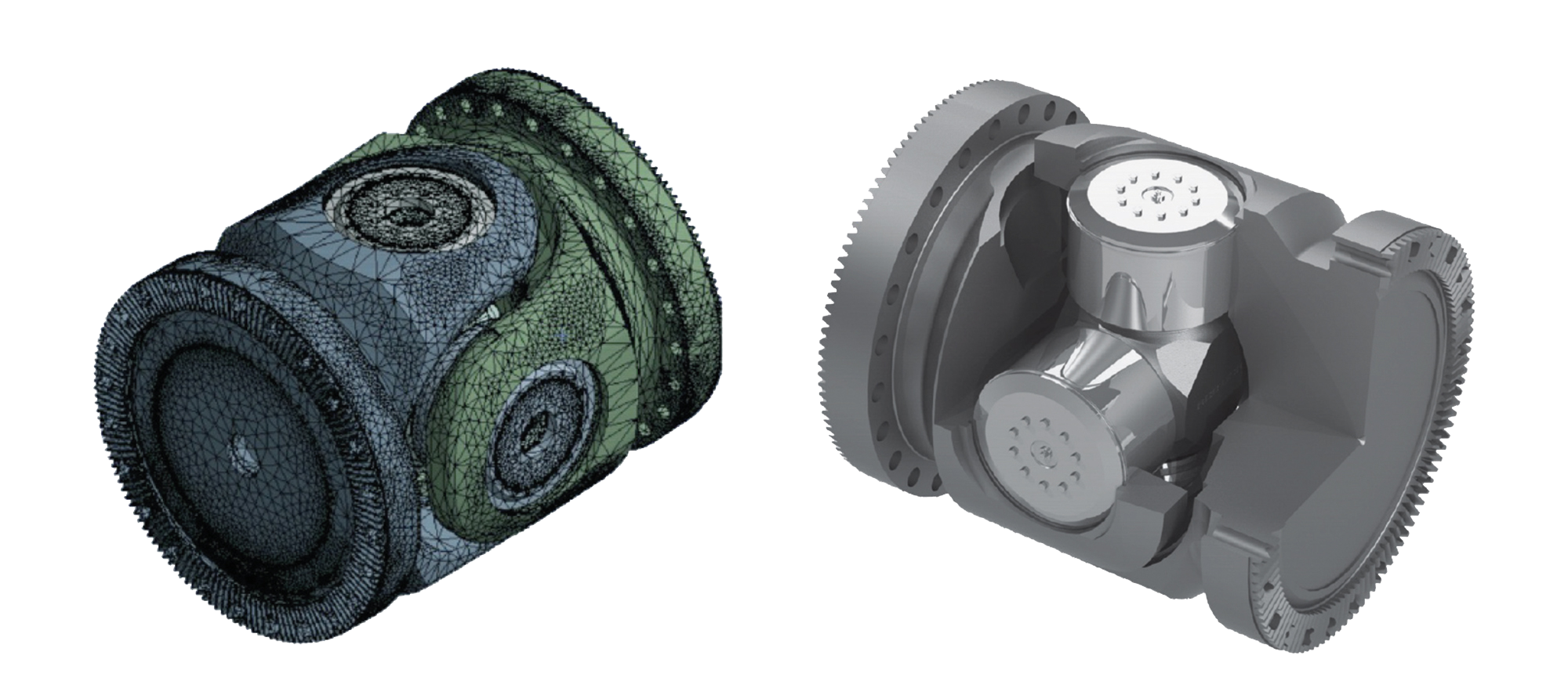

Our ABS engineers devised a plan of action, using the latest technologies in simulation and analysis (elasto-linear and elasto-plastic), to ensure that the design features matched the work requirements of the system and the technological capabilities of custom production and manufacturing with the highest precision of ACB and our manufacturers in Italy, MGS Gears.

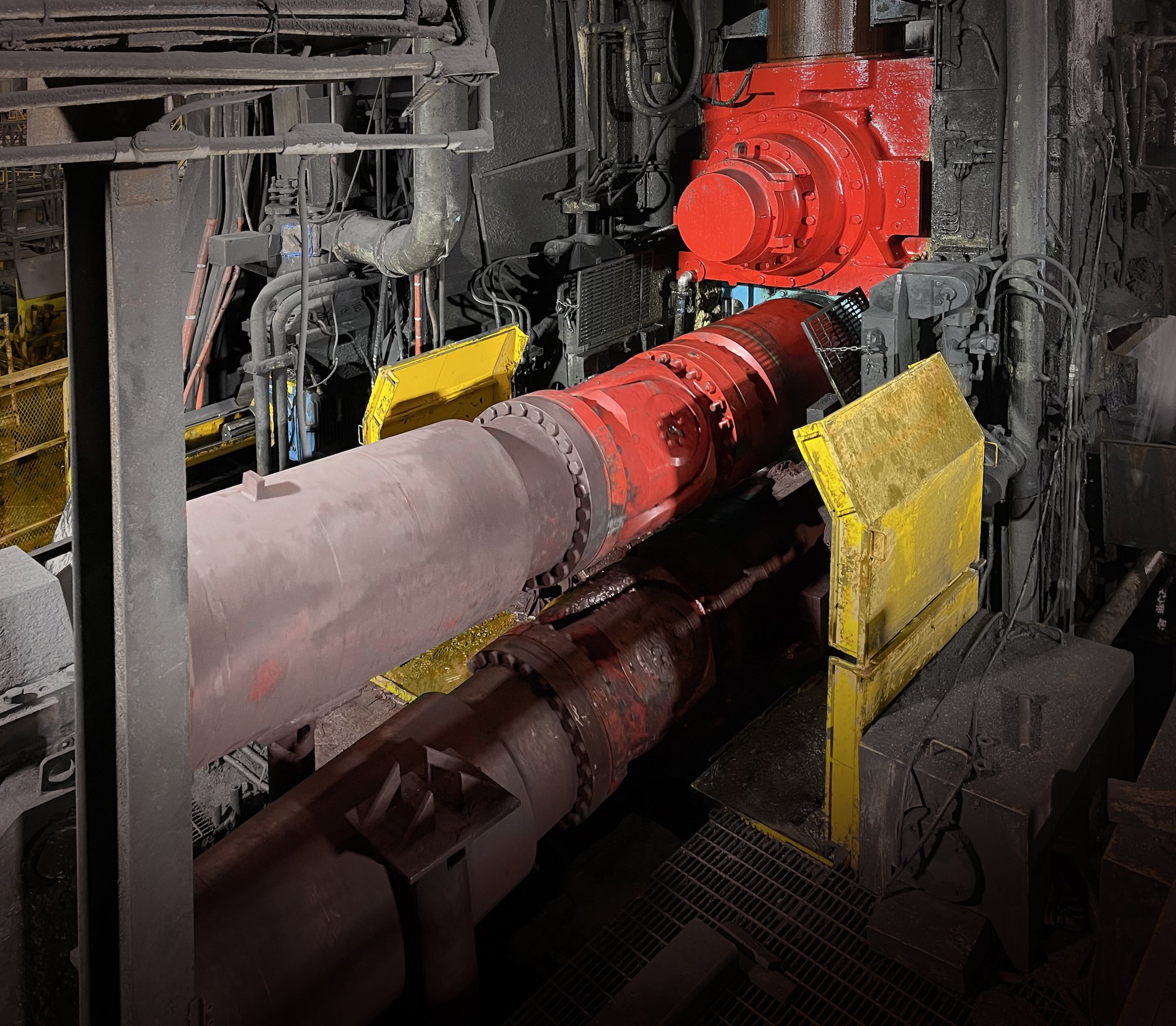

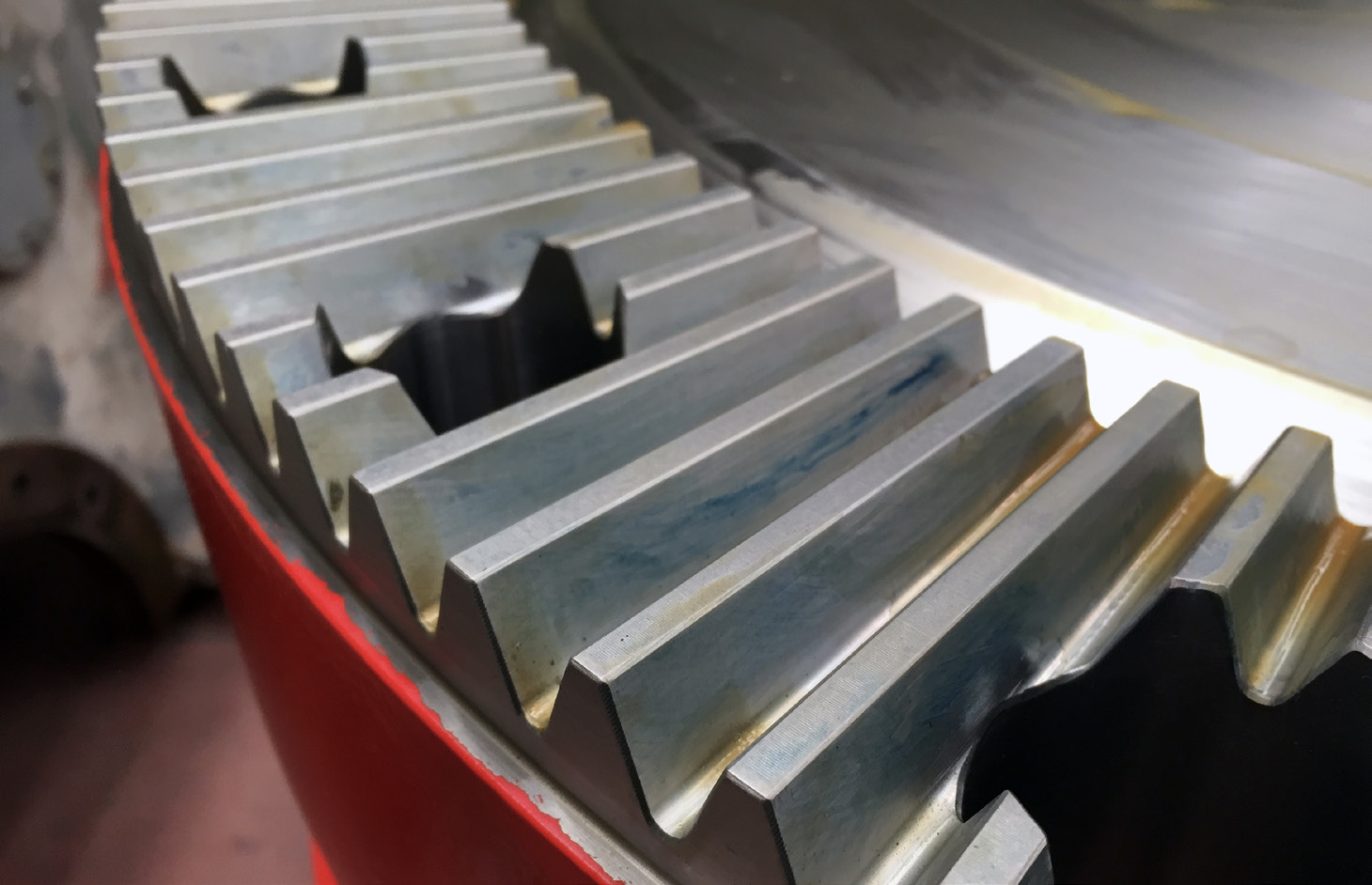

ABS designed Cardan Knuckles at MGS Gears facility

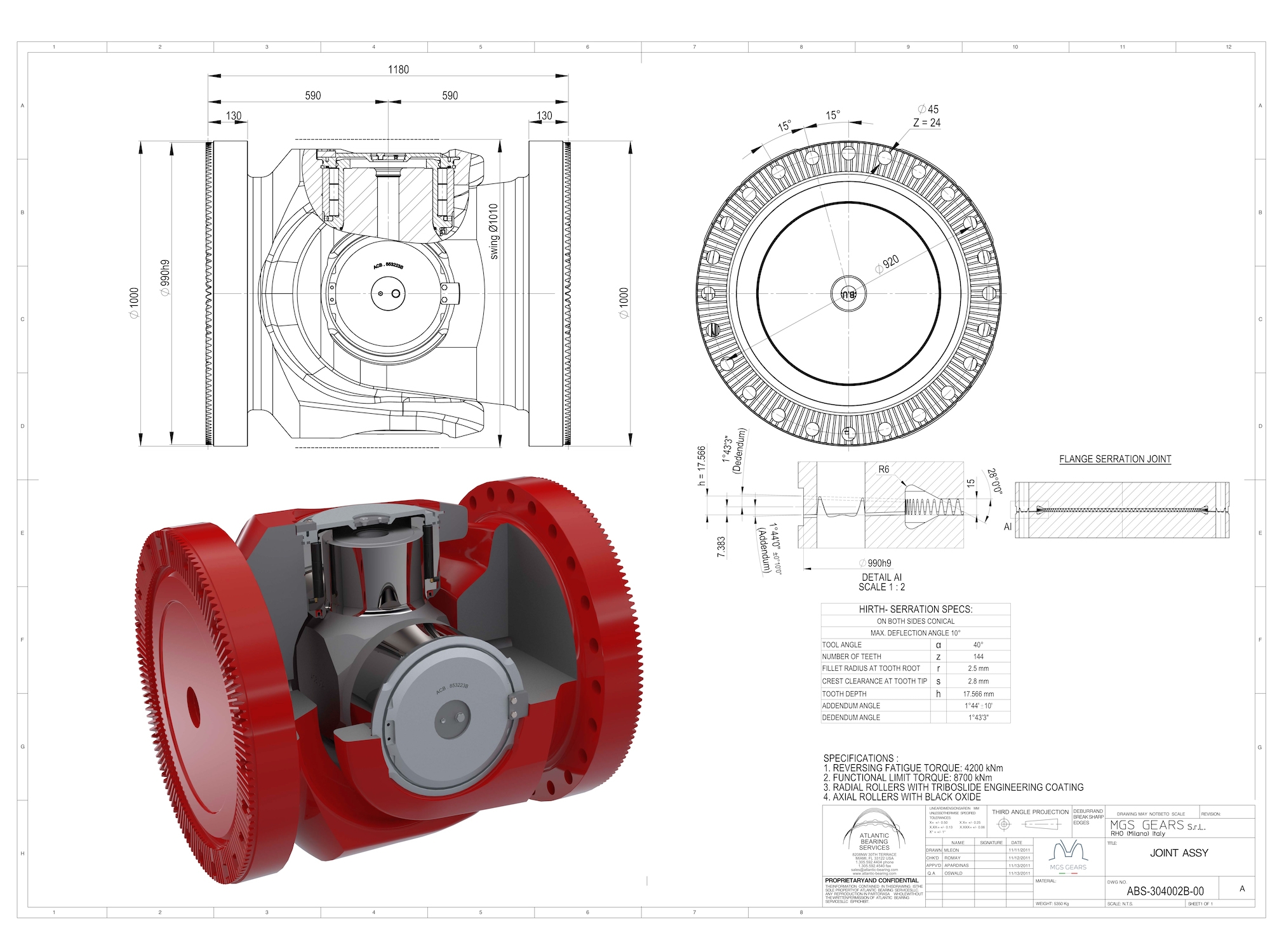

Gear Flage Contact Patter of the Cardan Knuckles

Rollers with optimum crown profile

TriboSlide coating on bearings

Quality and resistance in all mechanical components

- Highly alloyed forged steel knuckle was used instead of the original manufacturer’s cast steel.

- Bearings are from case-hardened and tempered steel to increase their surface hardness and resistance to impact loads.Highly alloyed forged steel journal cross have induction hardened raceways up to 8 mm in depth.

- This allows for knuckle recovery multiple times at a fraction of the cost of a new knuckle, thereby achieving optimally prolonging its service life.

Black Oxide anti-wear coating on journal cross and bushings

Optimal journal cross design

Special Seals

ABS, specialized customization and reliability for the Steel Industry!

ABS and its specialized brands have a long history of supplying customized products and solutions to the steel industry, ensuring superior performance, and extending the life of your industrial equipment. Each of the components that make up our cardan shafts is manufactured from the highest quality steels and steel alloys and meet the most stringent quality standards in the market.