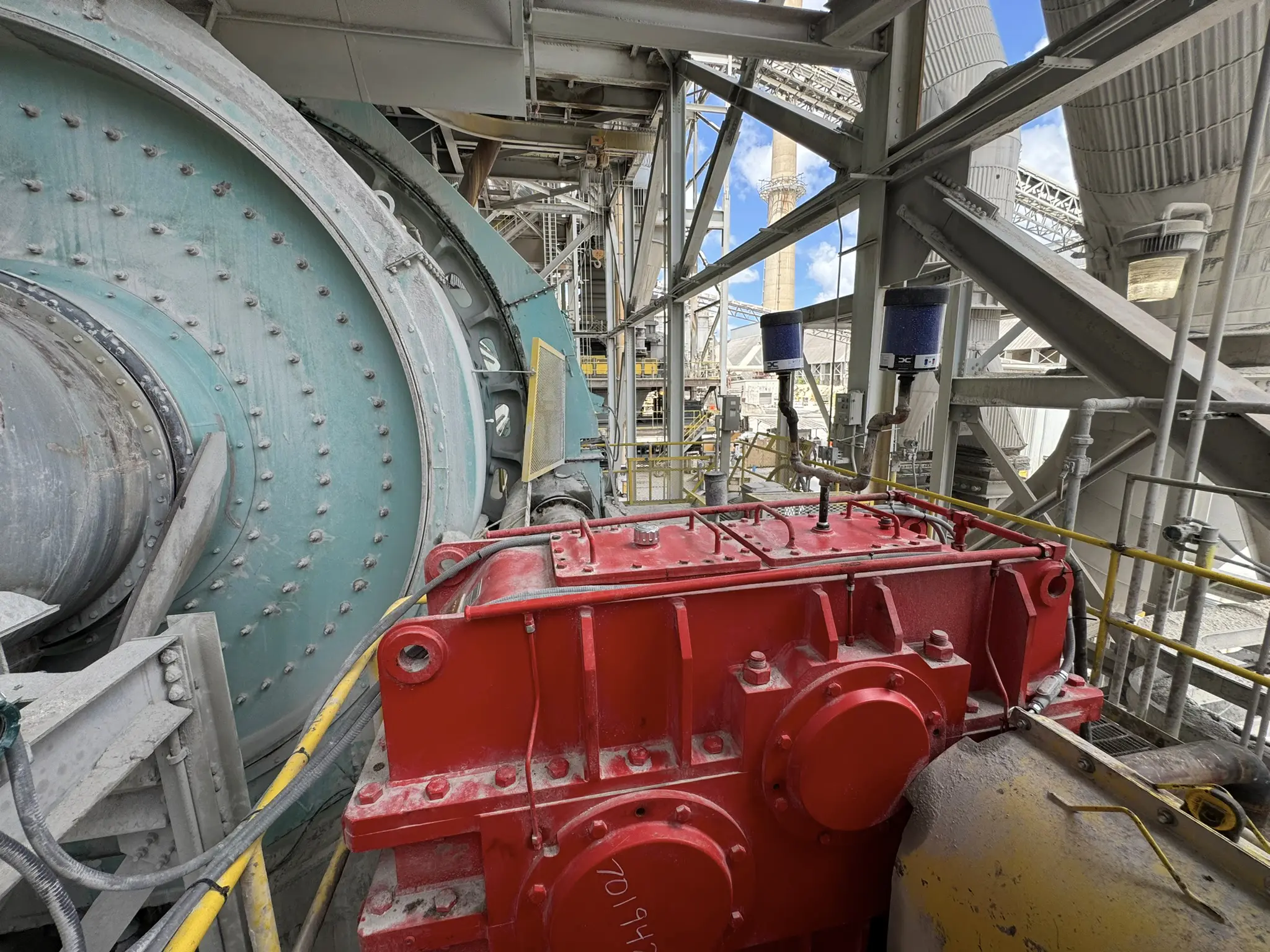

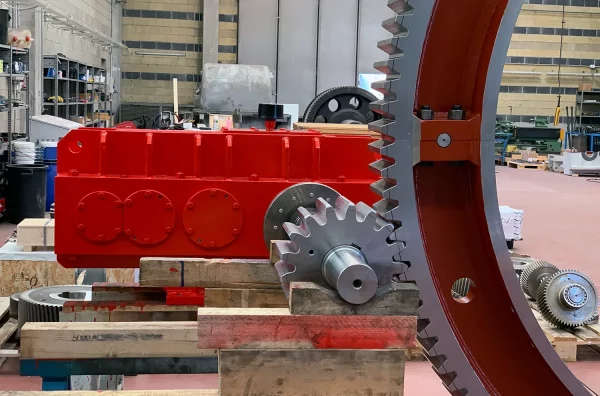

The CEMEX Brooksville plant sought to enhance the efficiency and reliability of its ball mill gearbox system. ABS engineered an advanced MGS Gearbox with a 400,000 N·m torque capacity, seamlessly integrating into the existing infrastructure. This breakthrough optimized performance, reinforced system durability, and underscored ABS’s expertise as a global reference in power transmission solutions for the cement industry.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.