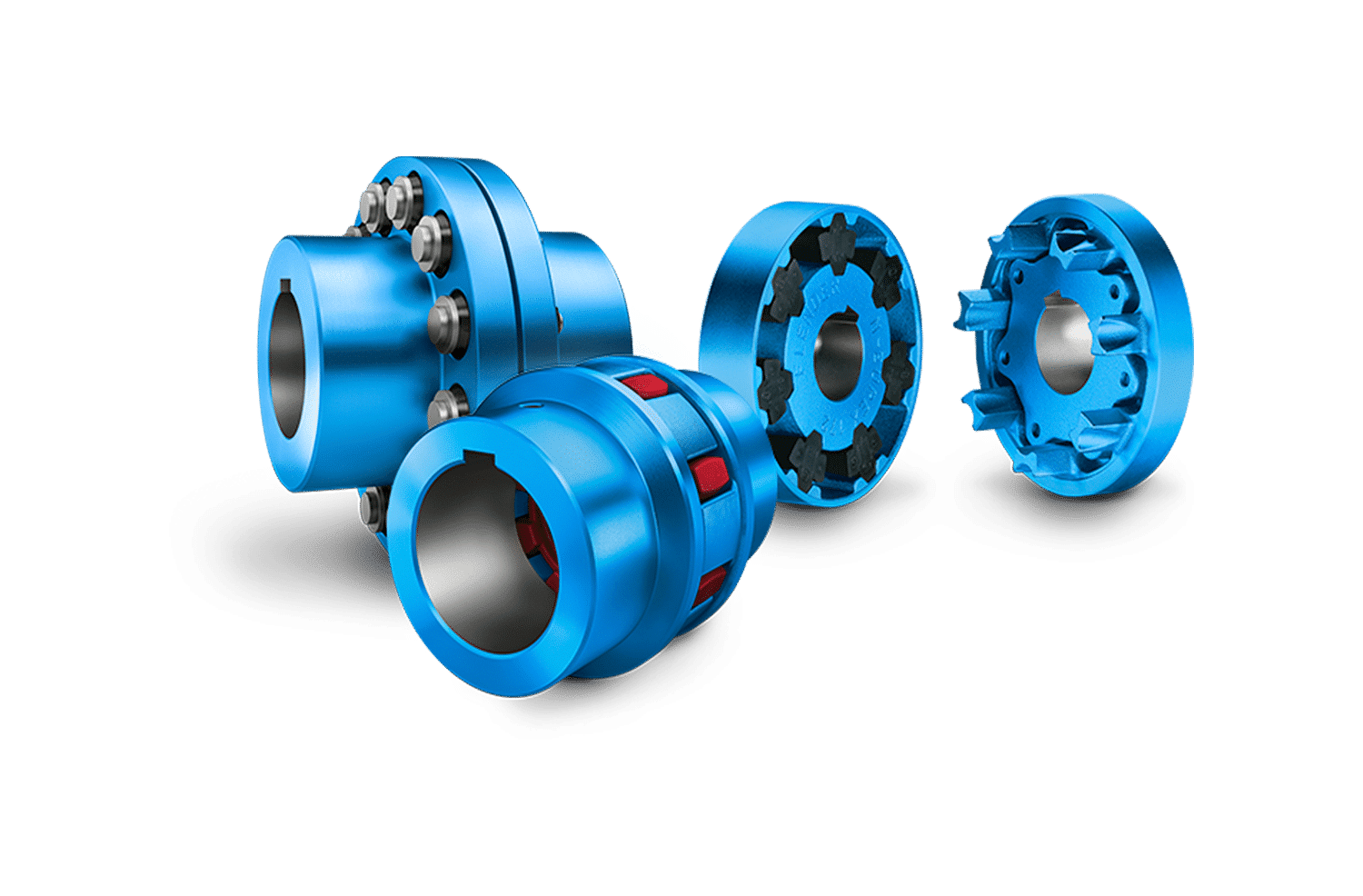

Elastic Couplings from ABS are designed to provide flexible and reliable power transmission while effectively damping vibrations and compensating for misalignments. These couplings are ideal for applications where shock absorption and the ability to handle angular, axial, and radial misalignments are essential. With their elastic elements, these couplings ensure smooth operation, reduce stress on connected components, and extend the lifespan of machinery.

Made from high-quality materials, ABS Elastic Couplings are resistant to wear and environmental factors, providing long-term durability in demanding industrial applications. They are easy to install and maintain, offering a cost-effective solution for industries like mining, cement, steel, and sugar processing, where vibration damping and flexibility are crucial.