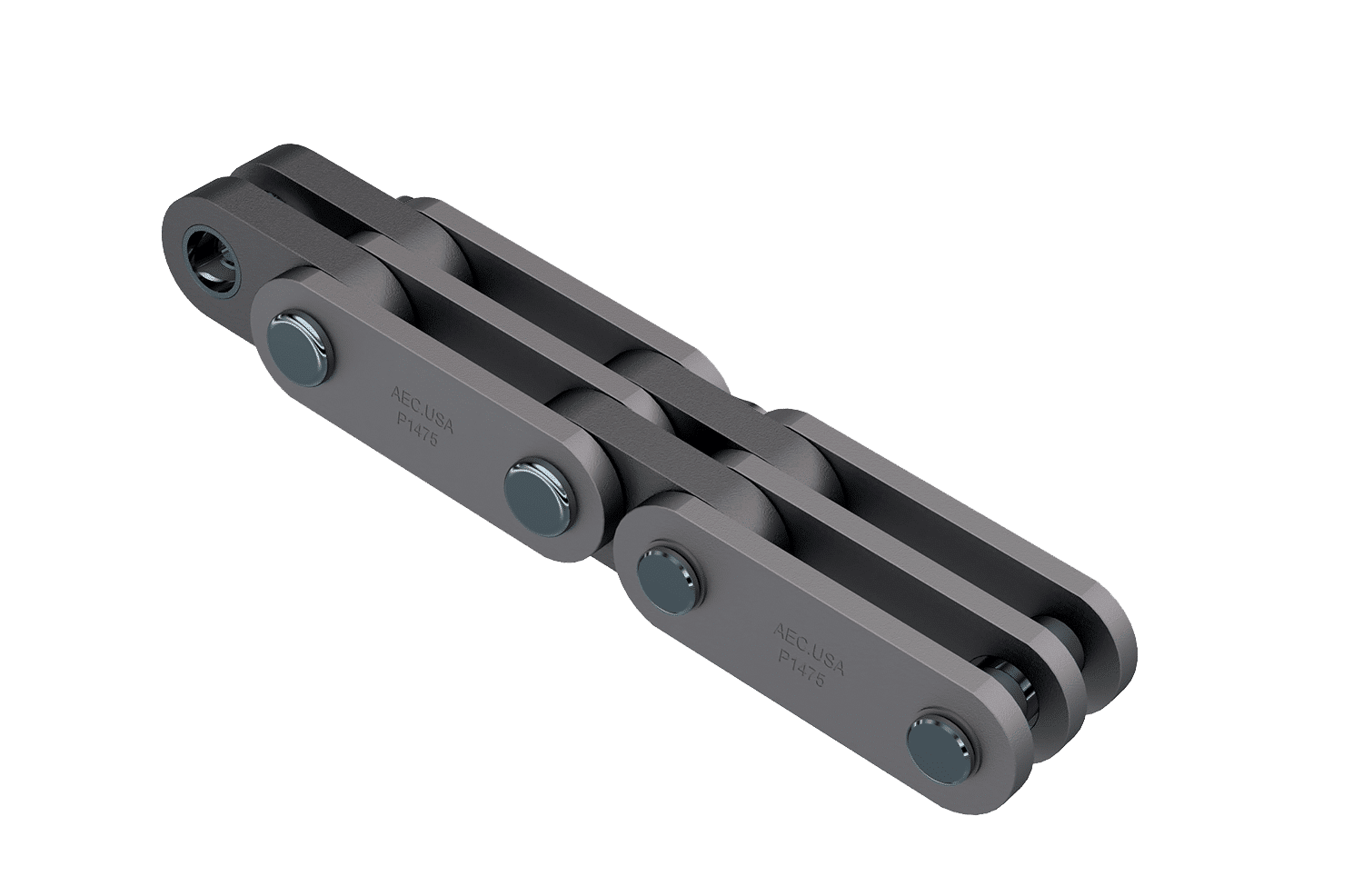

Steel Block & Draw Bench Chains from ABS are designed to deliver high performance in both slow-speed, drag-type conveyors and demanding draw bench applications. These chains feature robust construction with large bearing surfaces and high tensile strength, making them ideal for intermittent service in industries like steel mills. Their simple yet durable design ensures reliable operation in heavy-duty environments, while various attachment options allow for flexible use in transporting large objects directly on the chain or via auxiliary tracks.

For draw bench applications, ABS chains are made from high-grade alloy steels and undergo precision machining and heat treatment to meet the rigorous demands of metal drawing operations. The press-fitted pins prevent pin rotation, ensuring extended durability and consistent performance under severe load conditions.