Home » Our brands »

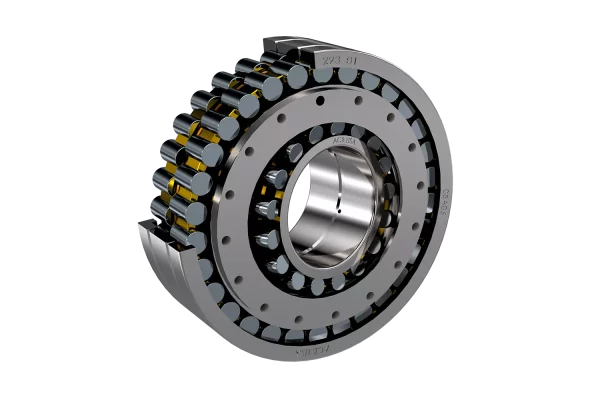

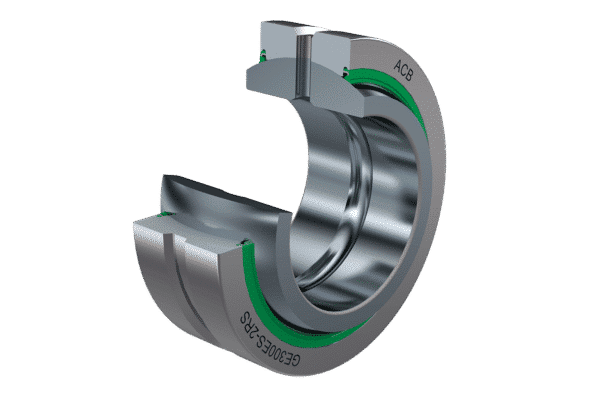

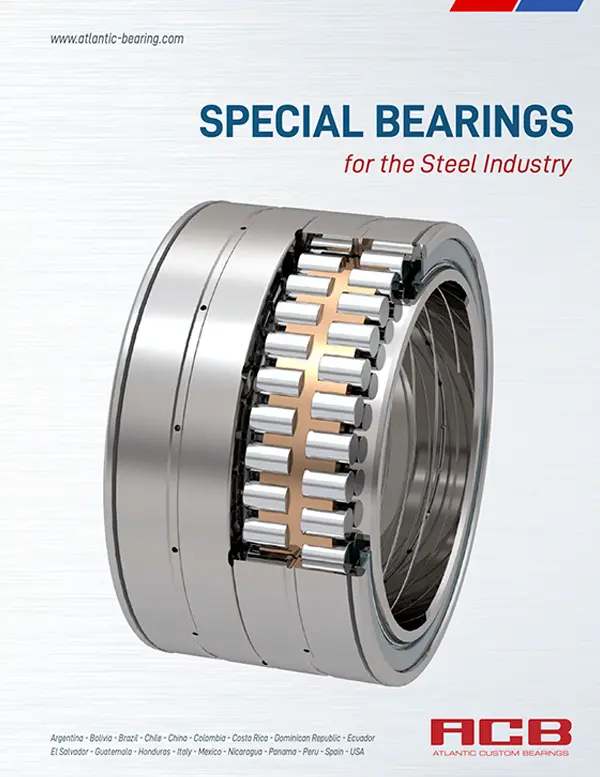

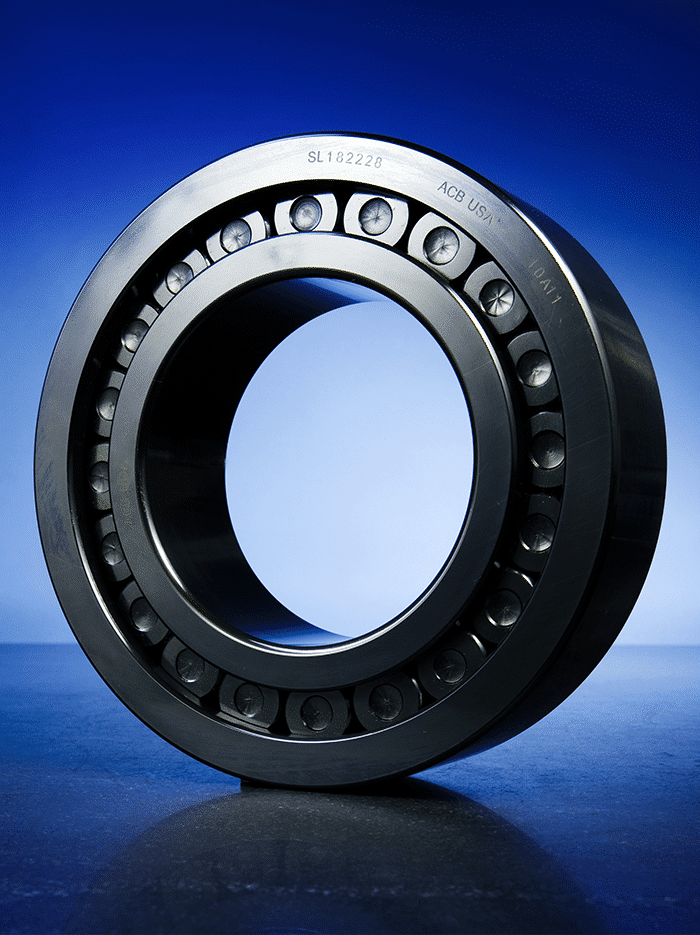

ACB Atlantic Custom Bearings

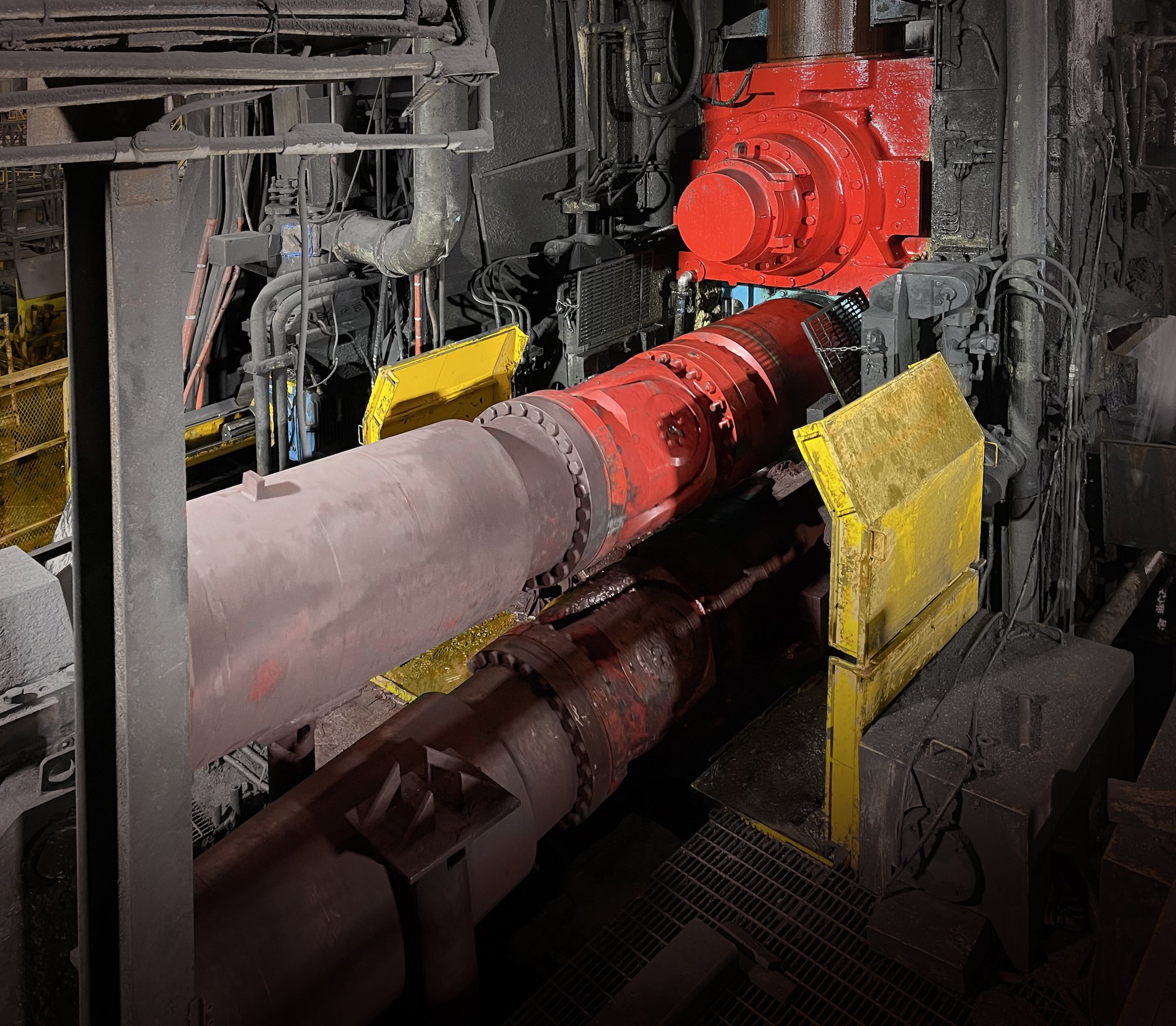

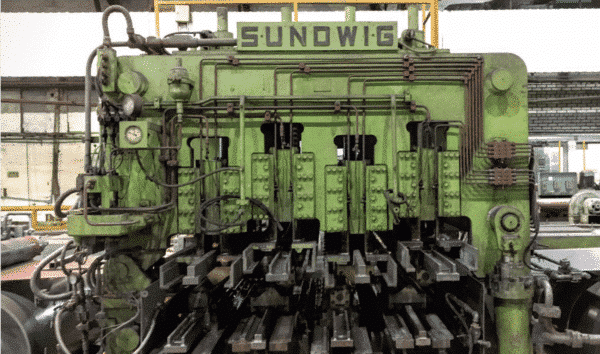

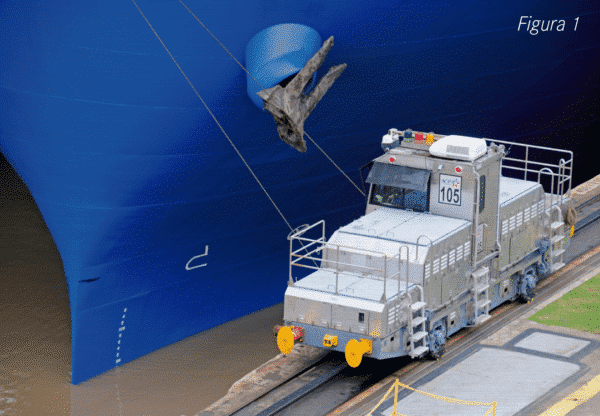

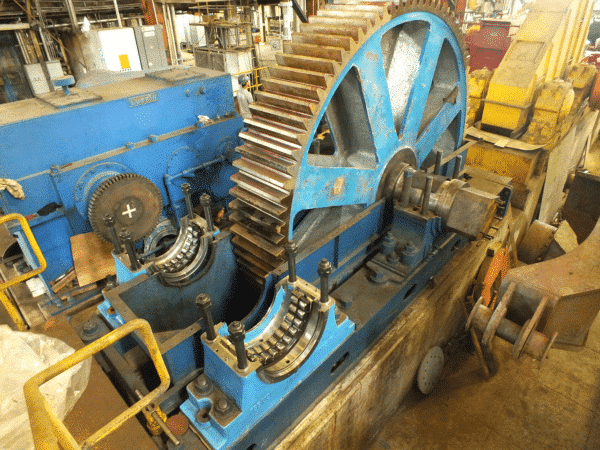

Since its birth in 2008, our custom-made bearing brand, ACB, has established itself among the most reliable bearing manufacturing brands for heavy industry (steel, mining, wind, sugar, cement…)

Our intention is not to compete with the leading bearing manufacturers but rather to offer an alternative that allows a high-quality solution tailored to the size of each customer’s needs.

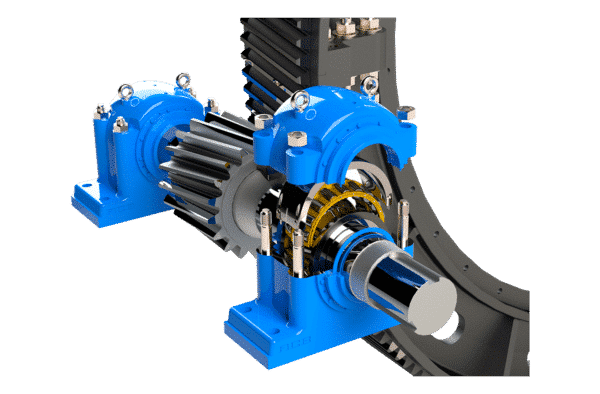

ACB Custom Bearings are already used in a wide variety of industrial applications. Our clients convey their satisfaction to us for the quality and performance of our products, competitive prices, delivery times, and the immediate response of our team of engineers specialized in each of them the industries we support.

And this recognition of our products and services has been worked on over the years, thanks to the implementation of a philosophy that is fundamentally committed to two values: proximity and willingness – we have factories spread over four continents and a local assistance team. in all the countries in which ABS Atlantic Bearing is present-, and due to our proven quality of design and manufacture -ACB bearings meet the highest quality standards throughout the entire production process-.

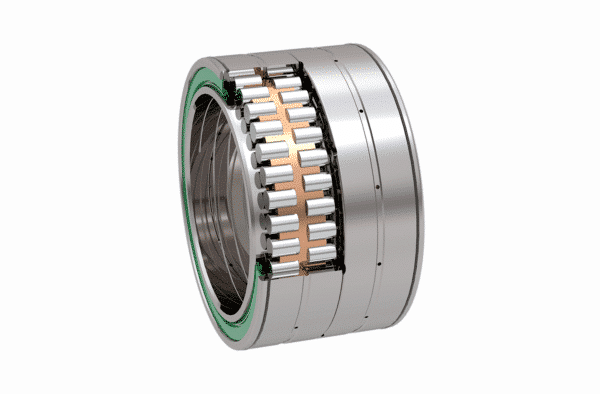

ACB bearings are subjected to a strict Quality Control (QC), where the specified manufacturing requirements are inspected, referencing the ISO 9001: 2000 standard. All key processes, from design to selection of materials, forging, heat treatment, grinding, and assembly operation, are carried out by our team of specialized engineers and supervised by our scientific department, and 100% of the parts are inspected during and after the manufacturing process in addition to performing and before shipment, a final inspection by sampling in our QC Laboratory.

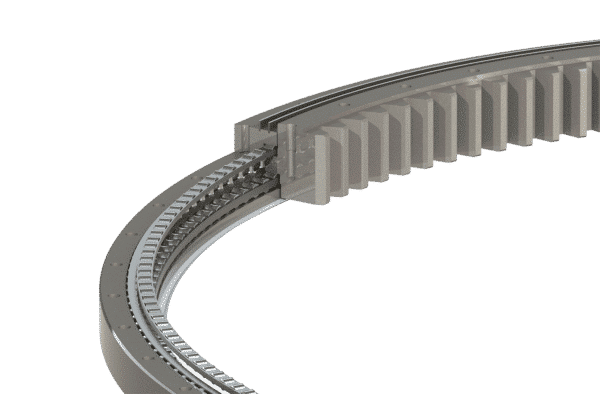

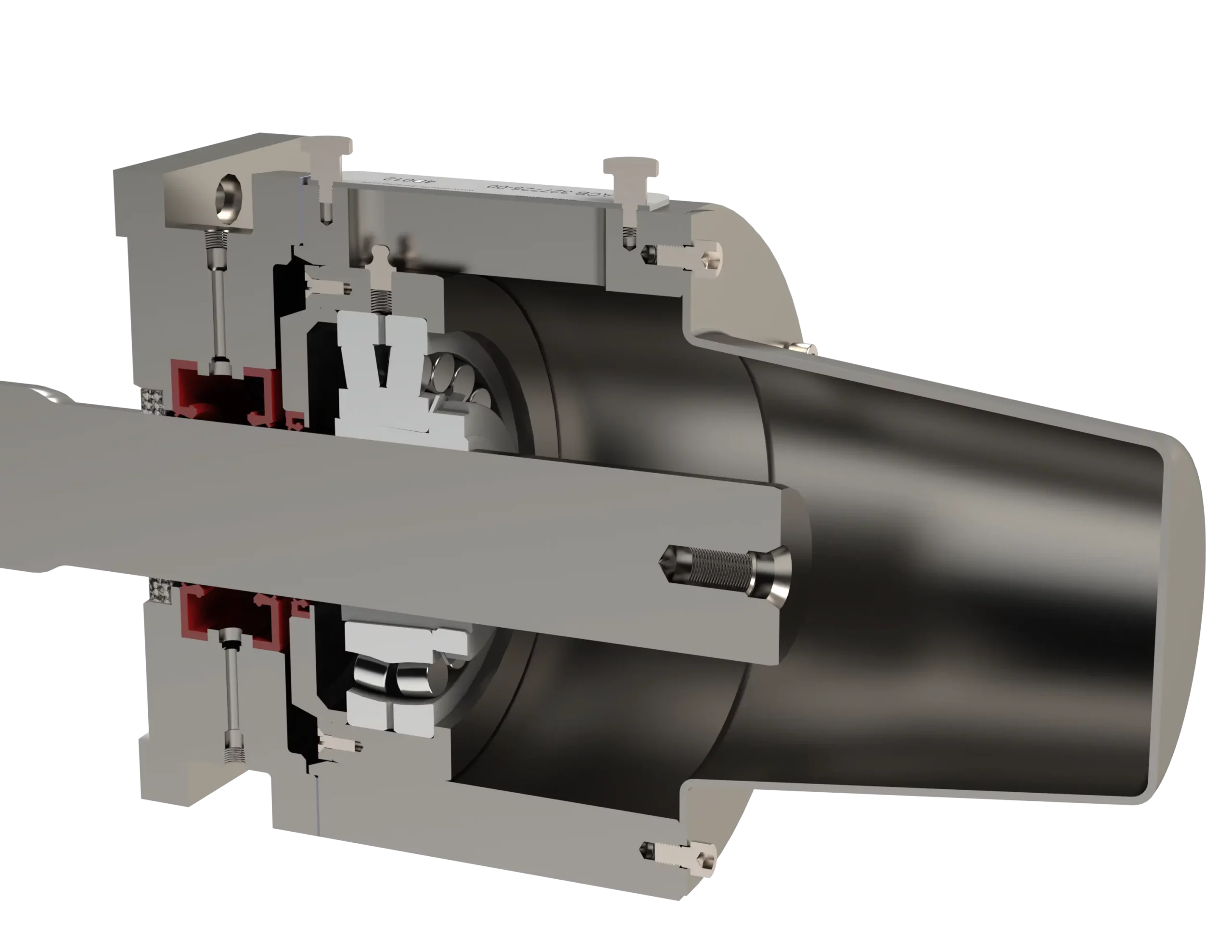

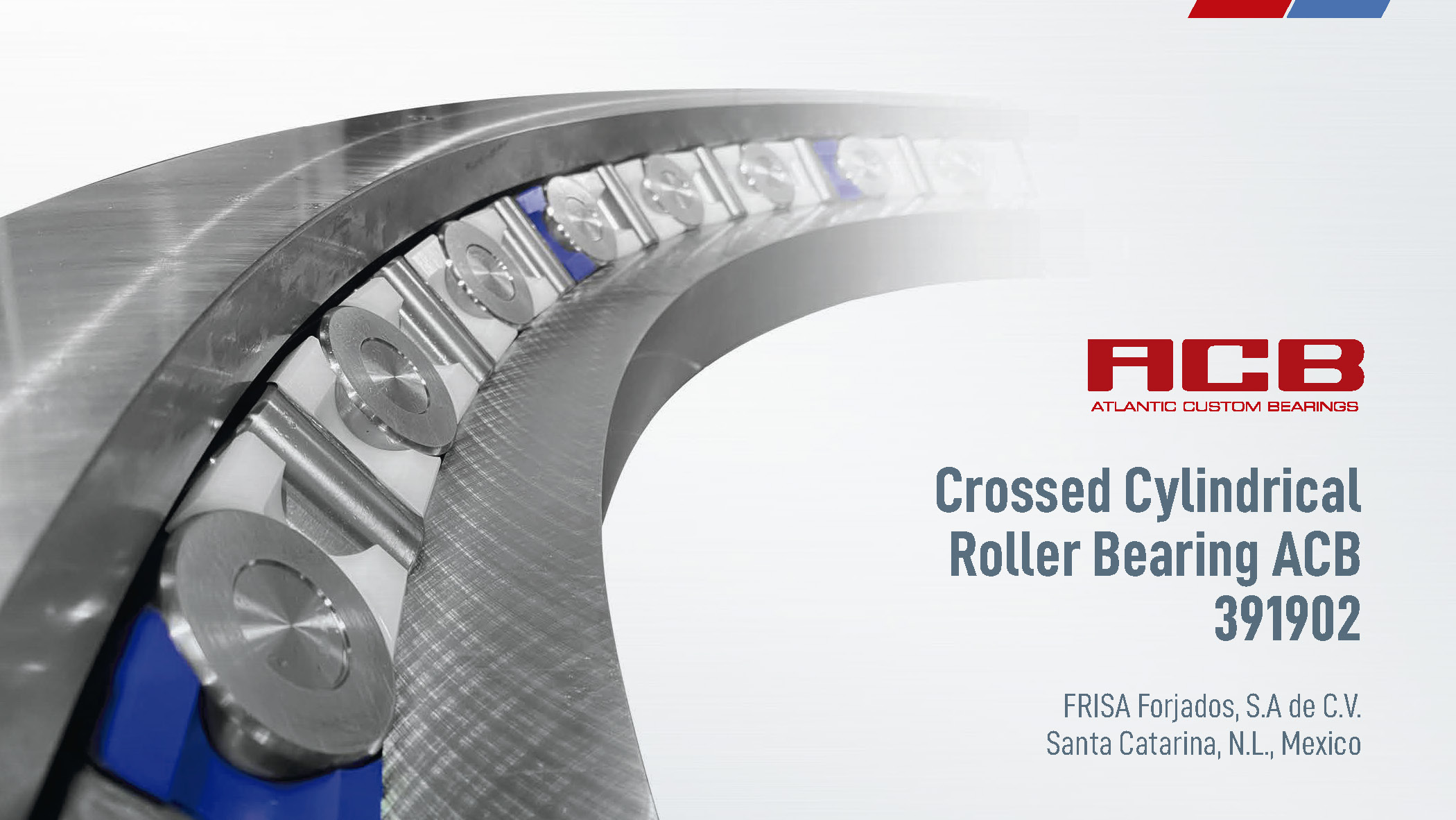

To minimize risks and achieve a response as adapted as possible, ACB also has the most advanced software for the design and evaluation of each bearing it manufactures. Through the well-known Finite Element Analysis (FEA), we realistically simulate the work of the bearing, subjecting it to the specific parameters and working conditions for which it will be required. Based on the results of the FEA, and if necessary, the component design can be modified to ensure its optimal performance in a real-world environment.

Moreover, if we have something clear, it is our inclination for projects that pose a challenge for our design and manufacturing department. We know that each mechanical component we design and manufacture represents a new step in offering our customers the most efficient and innovative custom-bearing solutions.

Features

- High quality bearingsteel.

- Internal Bearing design.

- Quality control / full trazability.

- Special Crown profile Rollers and raceways.

- Bainitically hardened inner and outer ring or case hardened bearing steels.

- Surface finish and form optimized rollers, races and ribs.

- Personalitation capabilities in real time.

- Special engineering coatings Surface treatment in roller and races.

- Real working conditions simulations using the most advance softwares in the market.

Advantages

- Low installation cost

- Easy replacement

- Reduction of downtime

- Maintenance efficiency

- Meets technical requirements for the vast majority of heavy industrial applications.