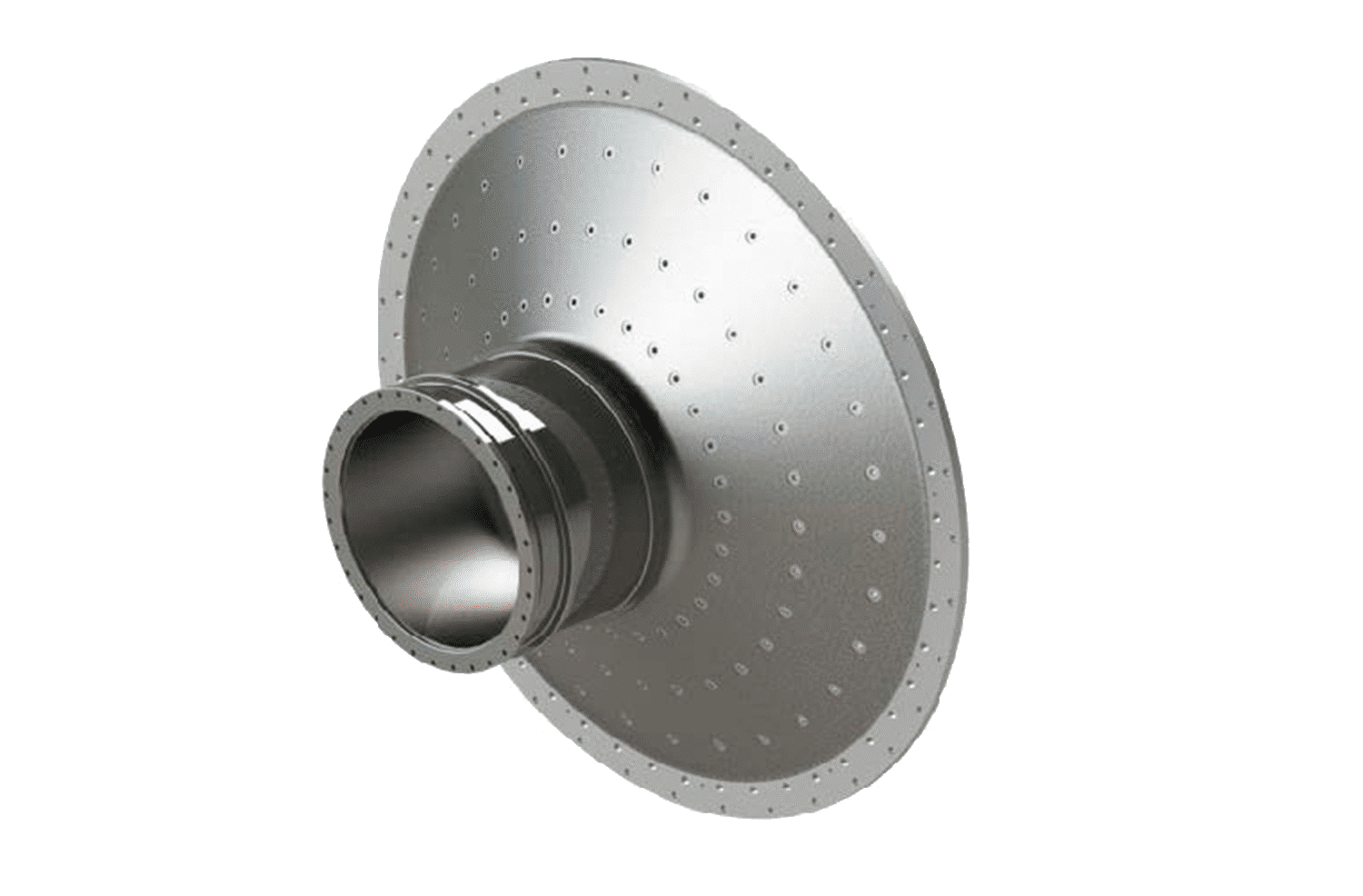

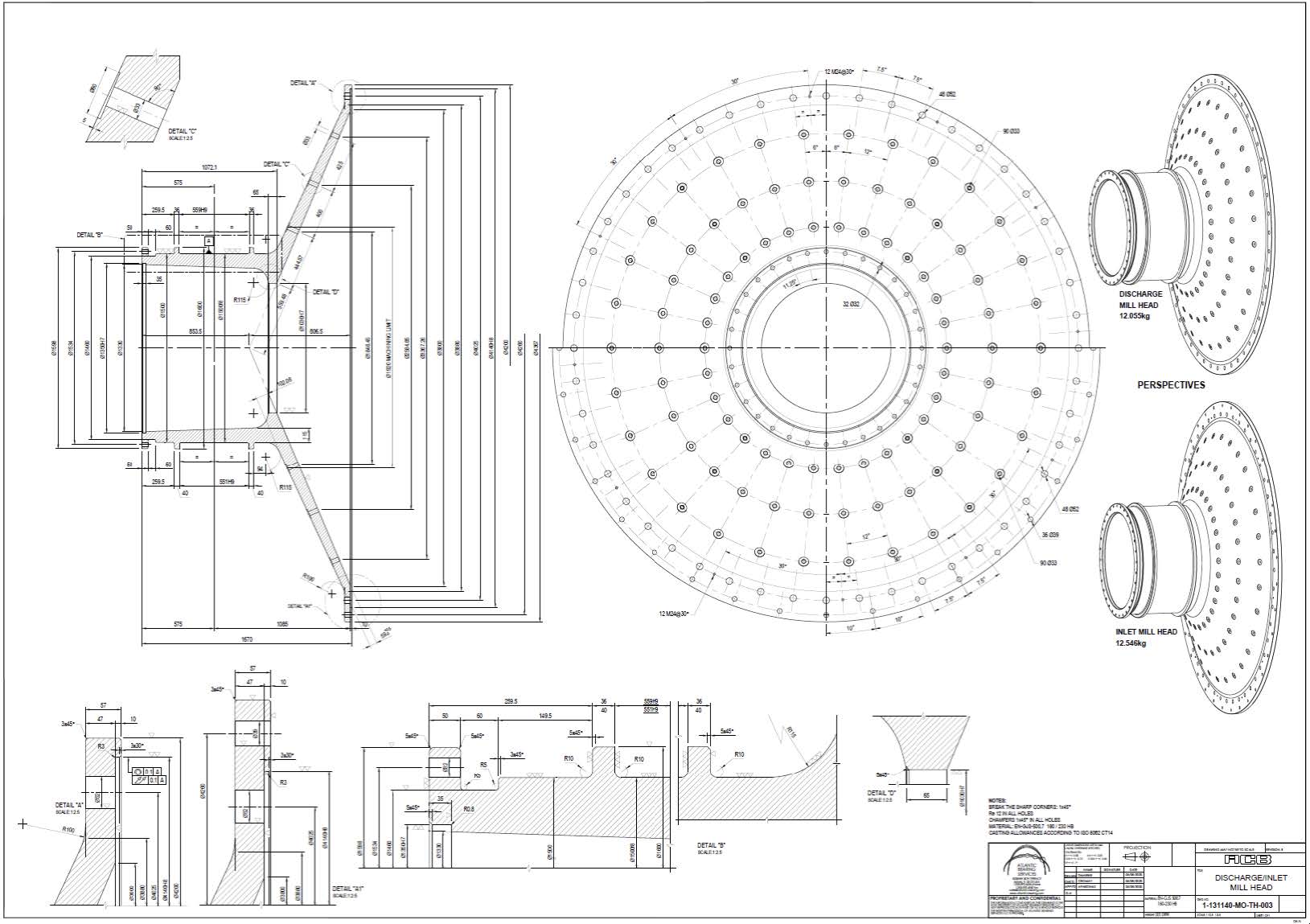

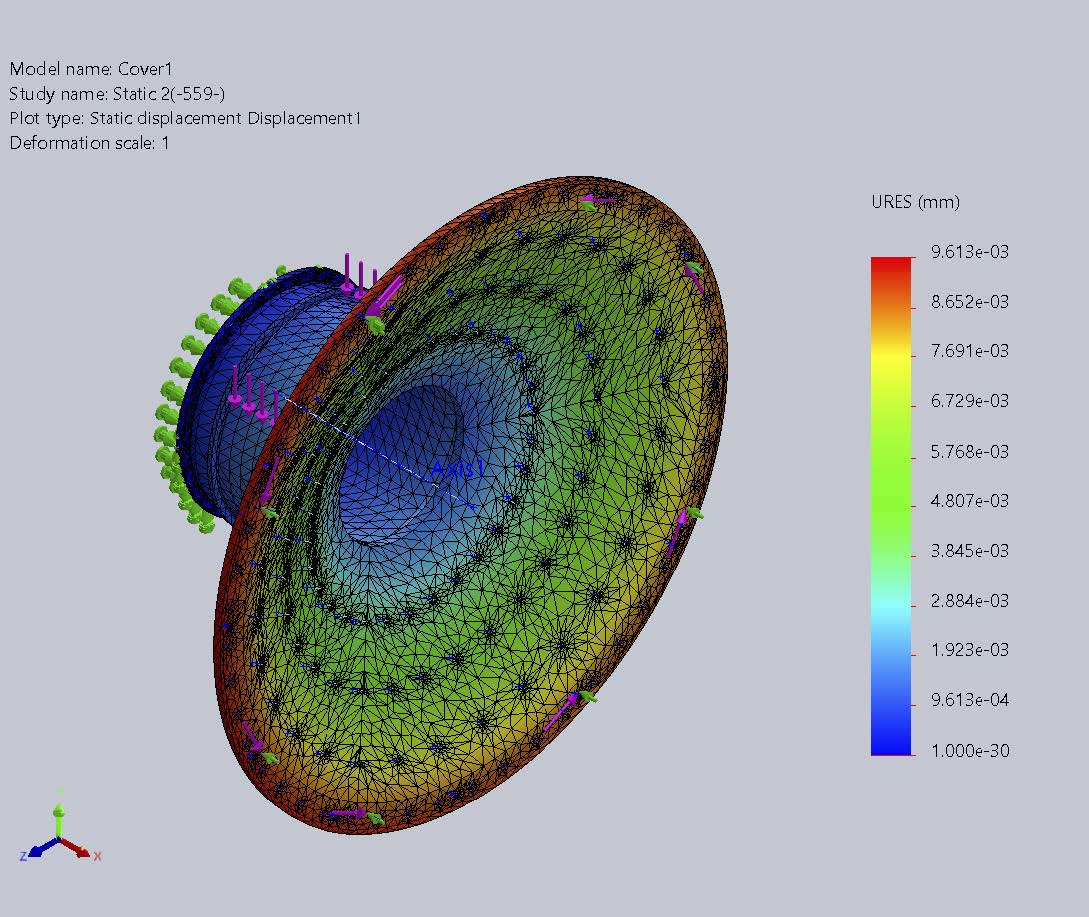

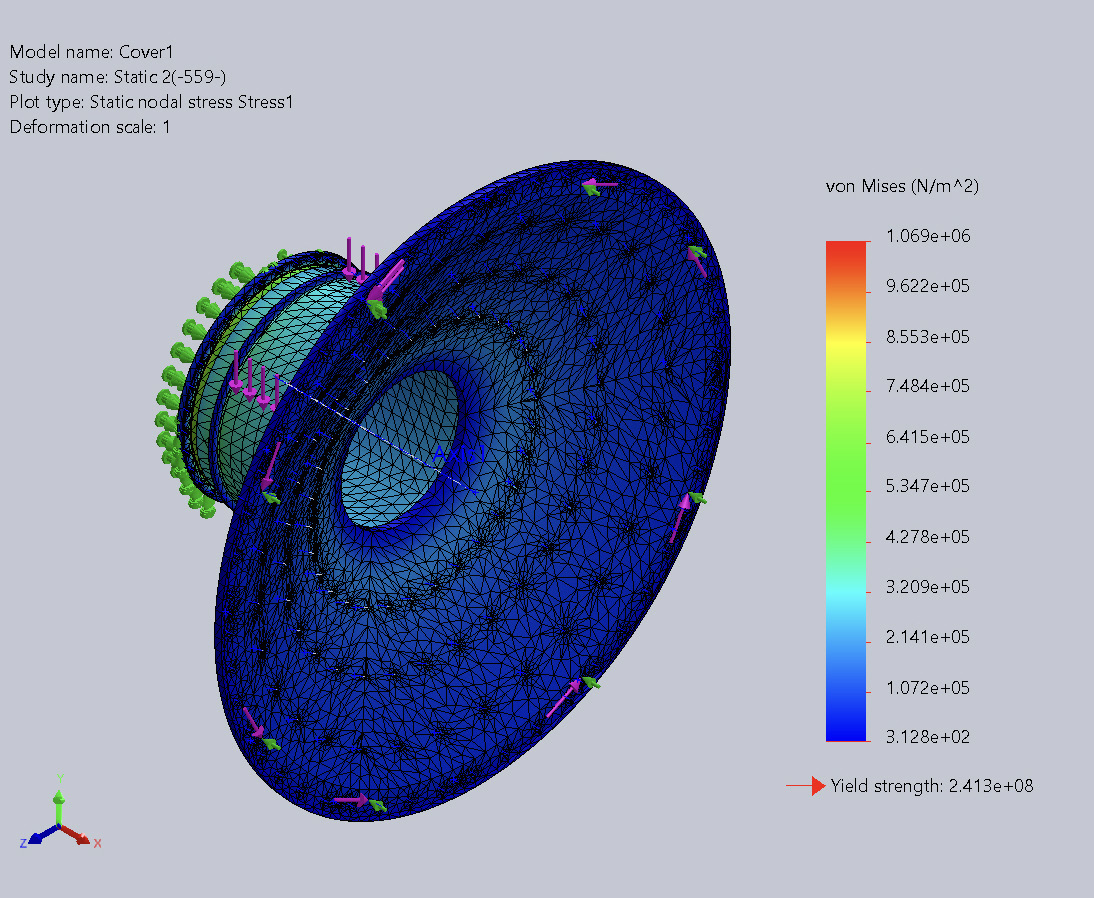

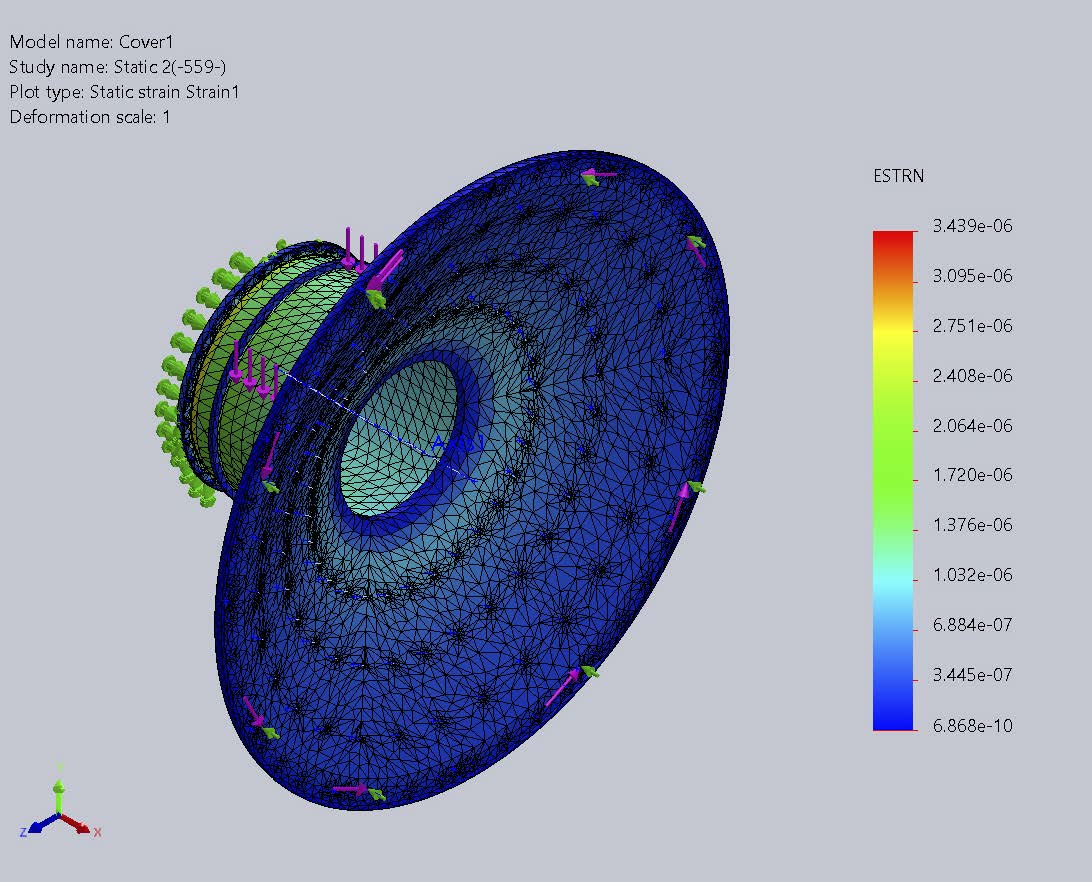

Mill Head Inlet and Discharge systems from ABS are designed to facilitate the efficient flow of materials in industrial milling operations. These components ensure smooth and controlled entry and exit of materials into and out of the mill, improving overall performance and productivity. Built to withstand the harsh conditions of heavy-duty milling processes, ABS mill head inlets and discharge systems are constructed from high-quality materials, ensuring durability and long-lasting operation in industries such as mining, cement, and sugar processing.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.