Looking for Special Bearings? At ABS, we design and manufacture solutions that perfectly fit your equipment needs, offering customized bearings tailored to the specific requirements of each industry. With specialized computer simulation laboratories, tribology expertise, fatigue and structural analysis, and state-of-the-art test centers, our high-quality manufacturing facilities deliver precision and reliability worldwide.

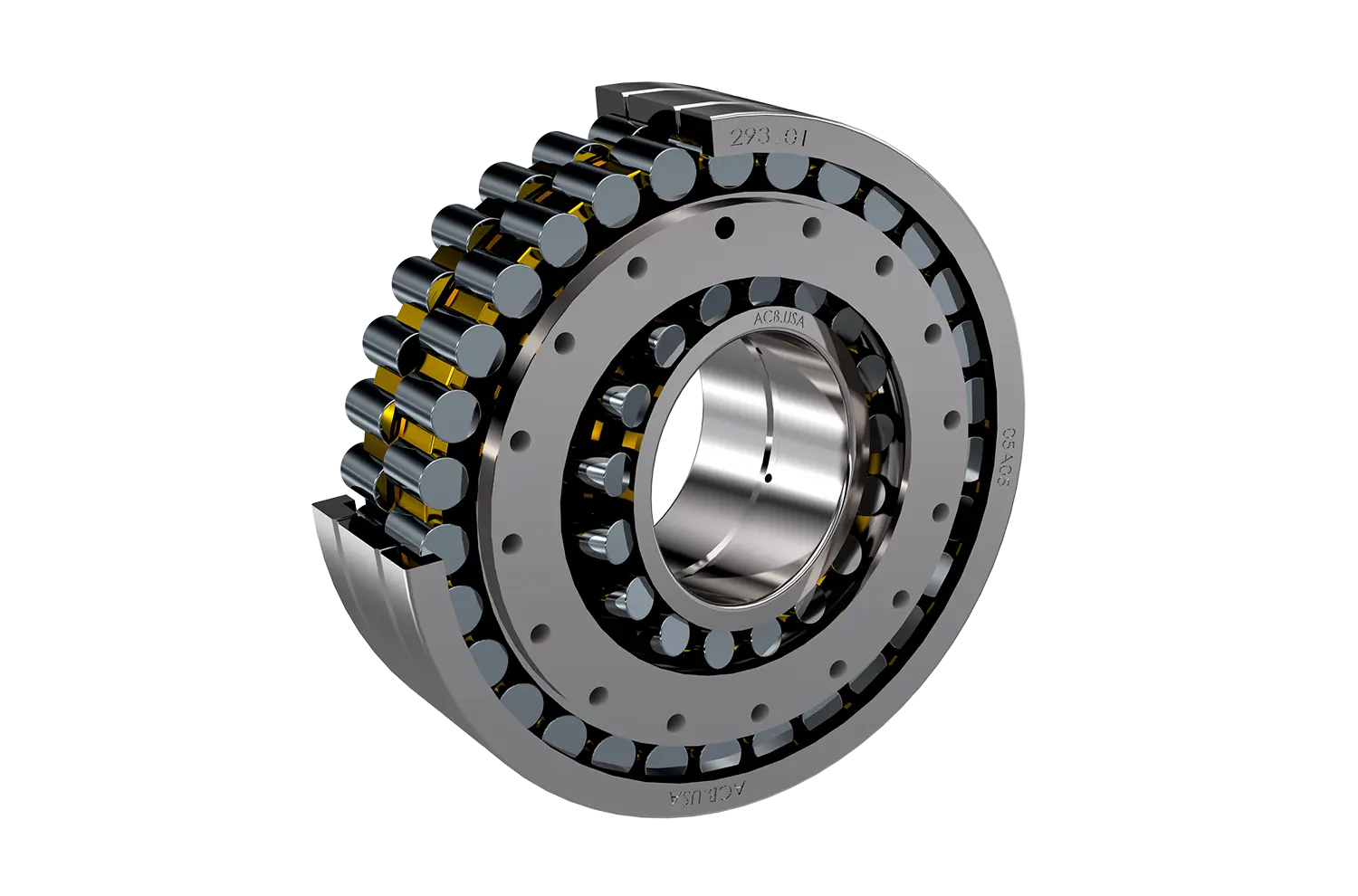

ACB Special Bearings from ABS are custom-engineered to meet the unique demands of industries operating under extreme conditions. Whether for high temperatures, corrosive environments, or specialized machinery, ABS bearings provide precision, durability, and reliability. These bearings are essential for sectors such as steel, cement, mining, aerospace and defense, and renewable energy, where conventional bearings may fall short of performance requirements.

By choosing ACB Special Bearings, you are selecting a product backed by ABS, a trusted name in engineered solutions. Our bearings are designed to exceed expectations in critical applications, ensuring long-lasting performance and minimal downtime, even in the harshest environments.