Description

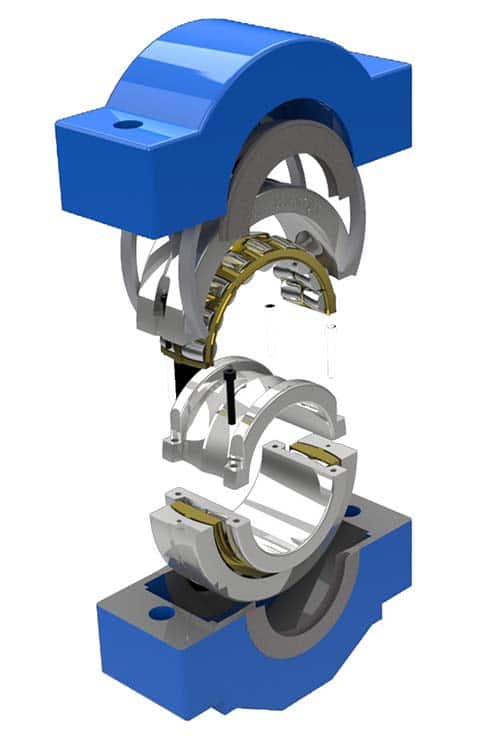

Split Spherical Roller Bearings from ABS are designed for easy installation and maintenance in demanding industrial environments.

In most mechanical production systems used in heavy industries such as sugar, cement, steel, and mining, spherical roller bearings are often located in hard-to-reach areas. When these bearings show signs of malfunction, checking and replacing them typically requires disassembling other components to gain access, leading to increased production downtime.

The main advantage of Split Spherical Roller Bearings is that they allow for quick and direct replacement without needing to disassemble other connected parts. This speeds up installation and replacement, significantly reducing operating costs and minimizing downtime.

Advantages

- Reduction of replacement time, especially when access to the bearing is complex.

- Reduction of assembly time.

- Production downtime reduction.

- Interchangeable and compatible with standard solid spherical bearings, with and without adapter sleeve.

- Simple mounting in split pillow block housings.

- Modular design and construction that saves engineering and maintenance related costs.

Key Features

- Split design: Enables easy installation and maintenance without the need to disassemble surrounding equipment.

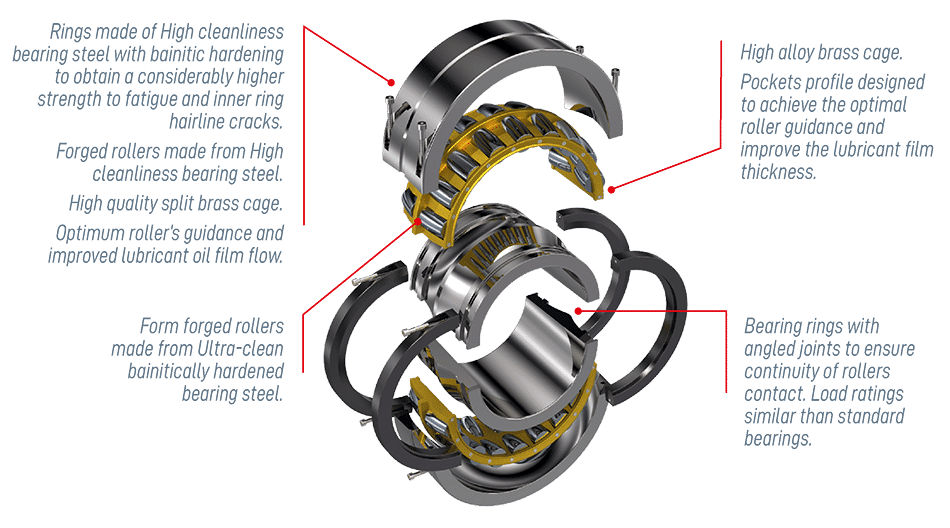

- Rings made of High cleanliness bearing steel with bainitic hardening to obtain a considerably higher strength to fatigue and inner ring hairline cracks.

- Forged rollers made from High cleanliness bearing steel.

- High quality split brass cage.

- Optimum roller’s guidance and improved lubricant oil film flow.

- Form forged rollers made from Ultra-clean bainitically hardened bearing steel.

- High alloy brass cage.

- Pockets profile designed to achieve the optimal roller guidance and improve the lubricant film thickness.

- Bearing rings with angled joints to ensure continuity of rollers contact. Load ratings similar than standard bearings.

- Diameters: Available in sizes ranging from 100 mm to 1000 mm.

- Standard construction: Follows standard measurements and proportions for versatile use.

- Advanced sealing technology: Includes specialized connections for oil or grease access, ensuring optimal lubrication.

- Customizable materials: Various material options for rollers, rings, and cages, tailored to specific applications and requirements.

- High load capacity: Designed to handle heavy radial and axial loads in demanding industrial environments.

- Angular misalignment capability: Operates efficiently even with significant misalignment between the inner and outer rings.

- Reduced downtime: Facilitates quick inspection, replacement, and maintenance, minimizing operational disruptions.

- Durable construction: Engineered to withstand the stresses of heavy industrial applications with precision-manufactured components.

Industrial applications

- Mining: Used in conveyors and crushers where accessibility is limited and disassembly is costly.

- Cement Industry: Applied in large rotary kilns and material handling systems to handle high loads and reduce maintenance time.

- Steel Manufacturing: Ideal for rolling mills and other high-stress machinery where regular maintenance is required.

- Sugar Industry: Commonly used in sugarcane crushers and processing equipment to minimize downtime during maintenance.

- Paper industry: Split Spherical Roller Bearings are essential in machinery such as paper mills and presses, where the bearings are often located in hard-to-reach areas. The split design allows for easier maintenance and replacement without the need for extensive disassembly, significantly reducing downtime in continuous production environments. These bearings also accommodate misalignment and handle the high radial and axial loads that are typical in paper production processes.

- Heavy Machinery: Suitable for large rotating equipment that requires frequent bearing replacement or inspection. Conveyor systems, Mining Industry, Papermaking machinery, Processing plants, Belt drives, Support of drive pinions in mills and rotary kilns, Rolling mills, Propeller shafts, Ventilation units, Long shafts supported at different points, Crankshafts…