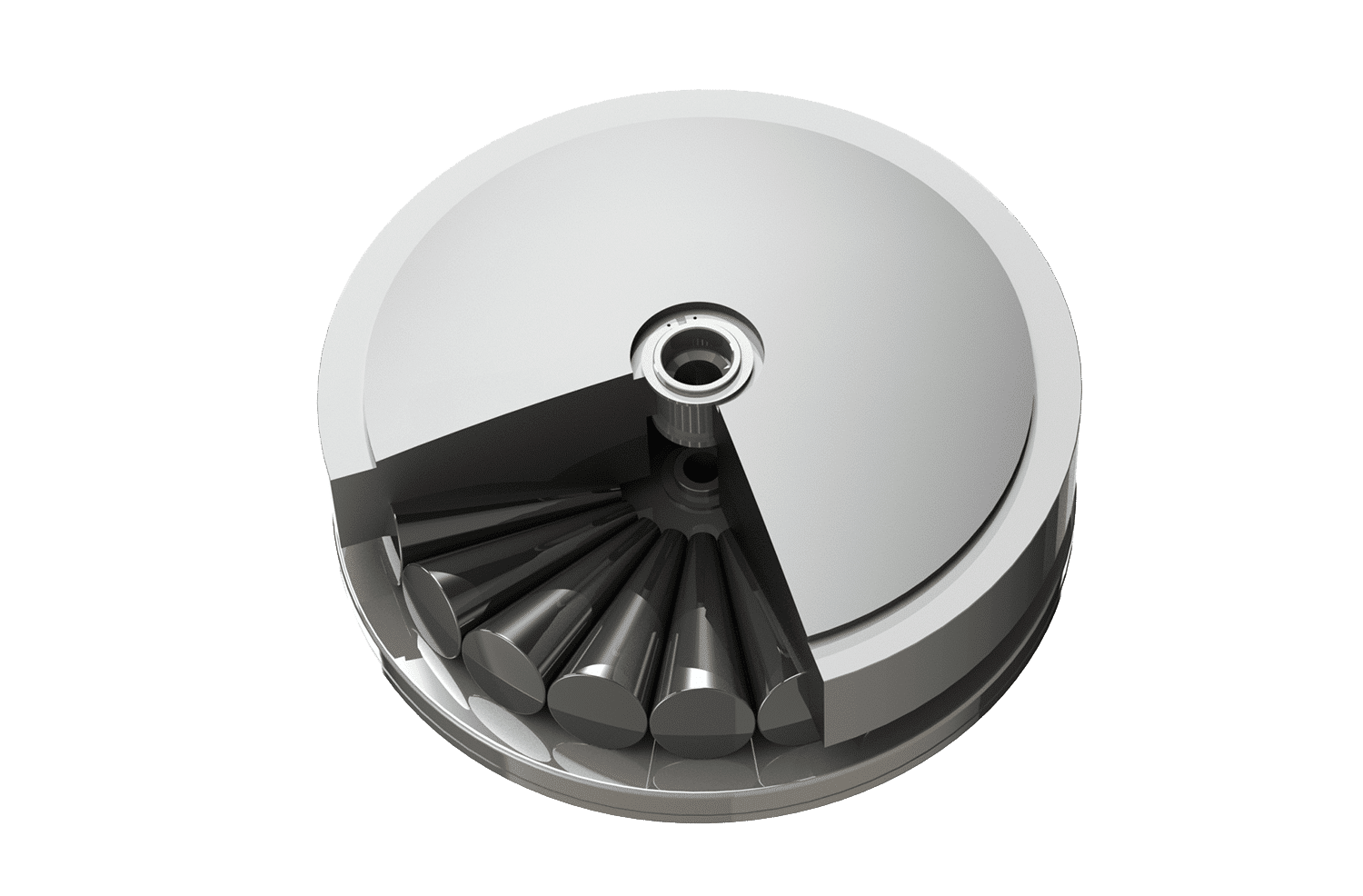

Tapered Roller Thrust Bearings from ABS consist of a shaft washer, a housing washer, and a cage with tapered rolling elements. This design optimizes load distribution, allowing the bearings to handle heavy axial loads, operate at high speeds, and reduce friction. These bearings are separable and non-latching, making them versatile for use in symmetrical or asymmetrical designs. The bearing washers and roller cage can be installed separately, providing flexibility during assembly. The precisely designed raceways of the housing and shaft washers ensure that the extension lines intersect at a single point on the bearing centerline, promoting smooth and accurate rolling motion.

The contact between the rib of the shaft or housing washer and the large, spherically ground roller ends is engineered to securely guide the rollers while forming a proper oil film, which enhances lubrication and reduces wear. Tapered Roller Thrust Bearings are especially suited for applications with extremely heavy axial and impact loads. They are available in three types: single direction, double direction, and screw-down spindle.

The screw-down spindle type is specifically designed for low-speed, heavy-load applications. The shaft washer surface is ground to a convex or concave spherical profile to match the ends of screw-down spindles, allowing for some misalignment during rotation. Additionally, the flat housing washer raceway accommodates spindle run-out, maintaining stability under heavy load conditions.