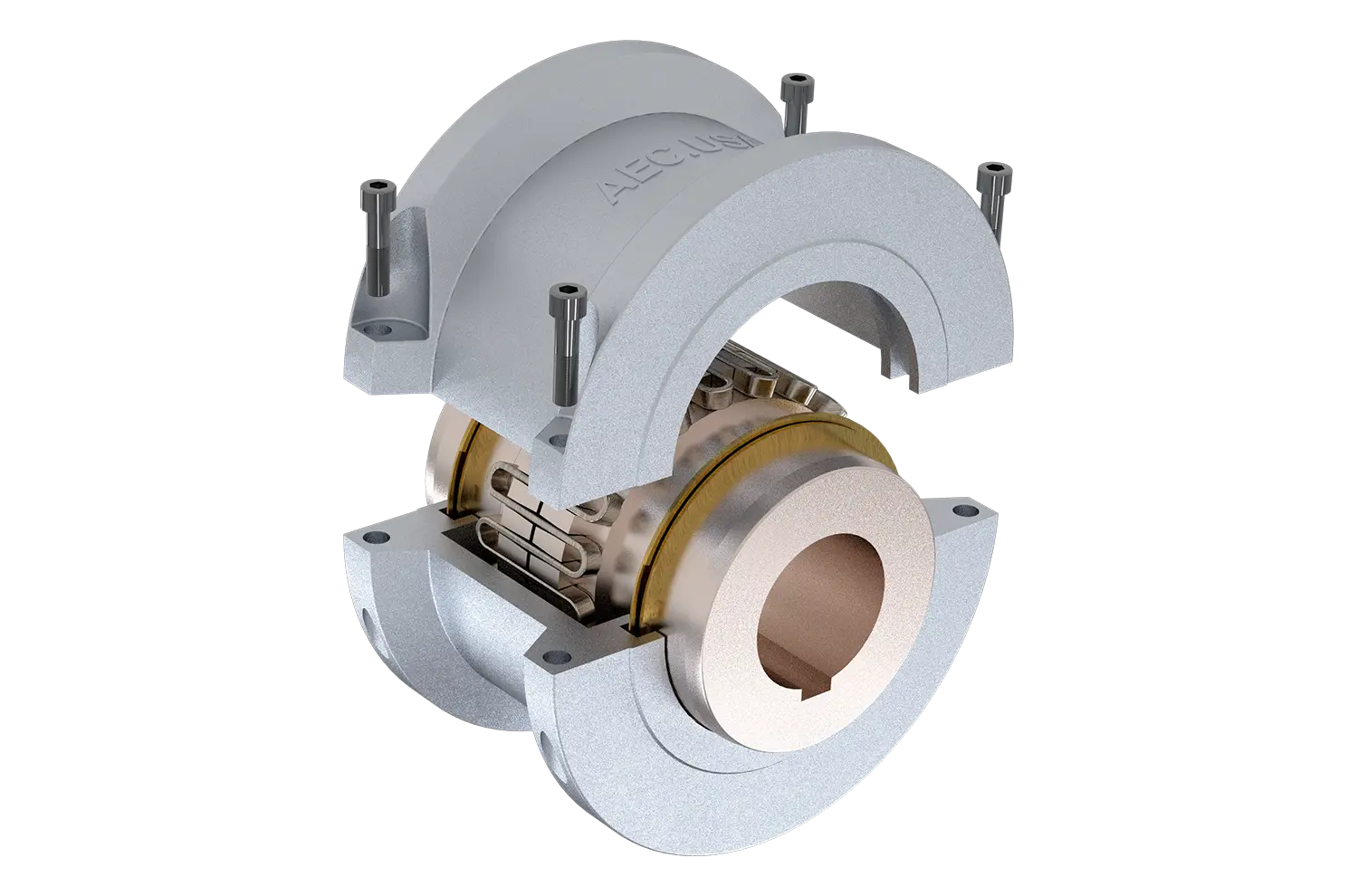

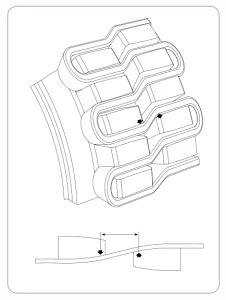

The AEC Grid Couplings are designed to handle significant torque despite their compact size. These all-metal flexible couplings are primarily used to reduce vibration and shock transmission while accommodating both angular and parallel misalignments within their operational limits. In the event of a heavy overload or excessive misalignment, the grid and cover act as a safety mechanism, failing to interrupt torque transmission and protect more expensive drive components from damage.

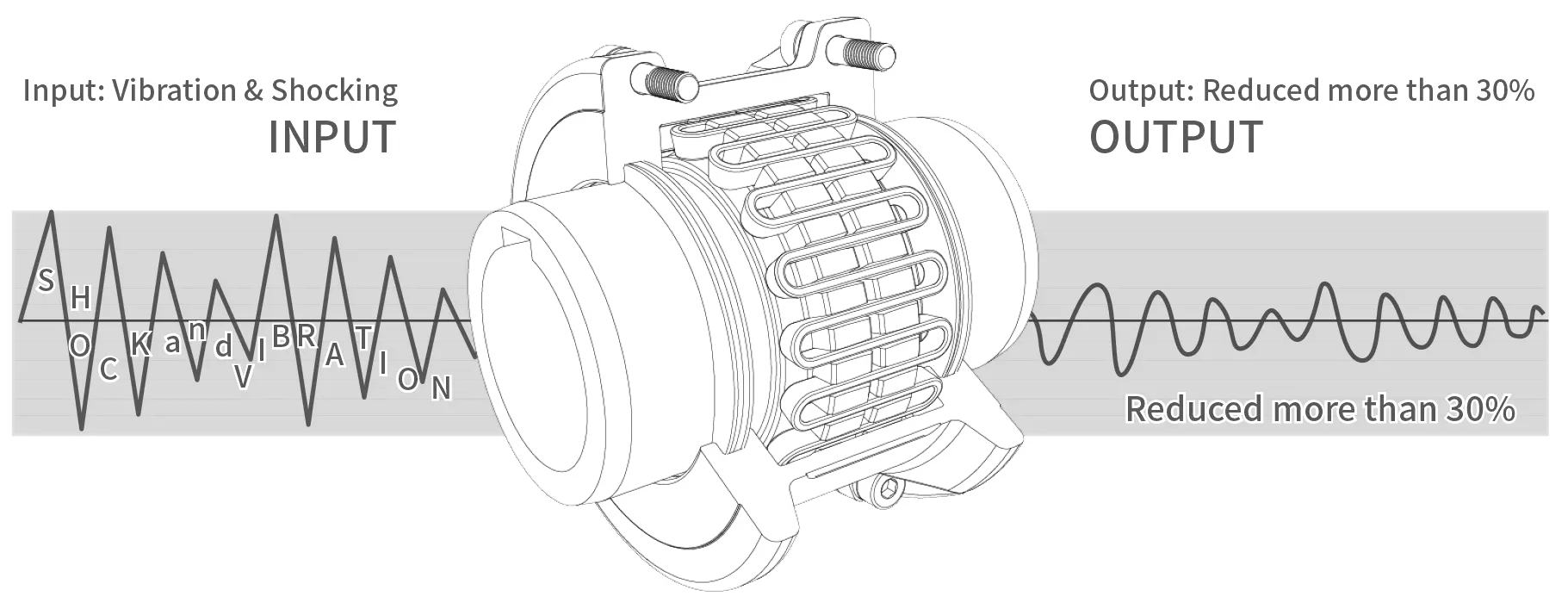

Compared to other couplings, grid couplings offer simpler installation and repair, and their high reliability leads to reduced and shorter maintenance inspections. ABS Grid Couplings are specifically engineered to provide flexible, efficient power transmission while safeguarding connected equipment from misalignment, shock loads, and vibration. The grid design absorbs impact and reduces vibration, extending the lifespan of both the coupling and the connected machinery.

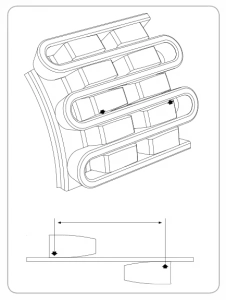

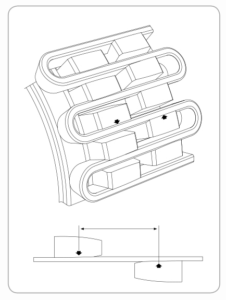

The flexibility of the grid element accommodates angular, radial, and axial misalignment, all while maintaining high torque transmission. These couplings are ideal for industries such as mining, steel, cement, and sugar, where dependable power transmission and the ability to withstand high loads and operational stresses are crucial. Their robust design ensures long-lasting performance even in harsh industrial environments, ultimately extending the service life of the machinery they support.

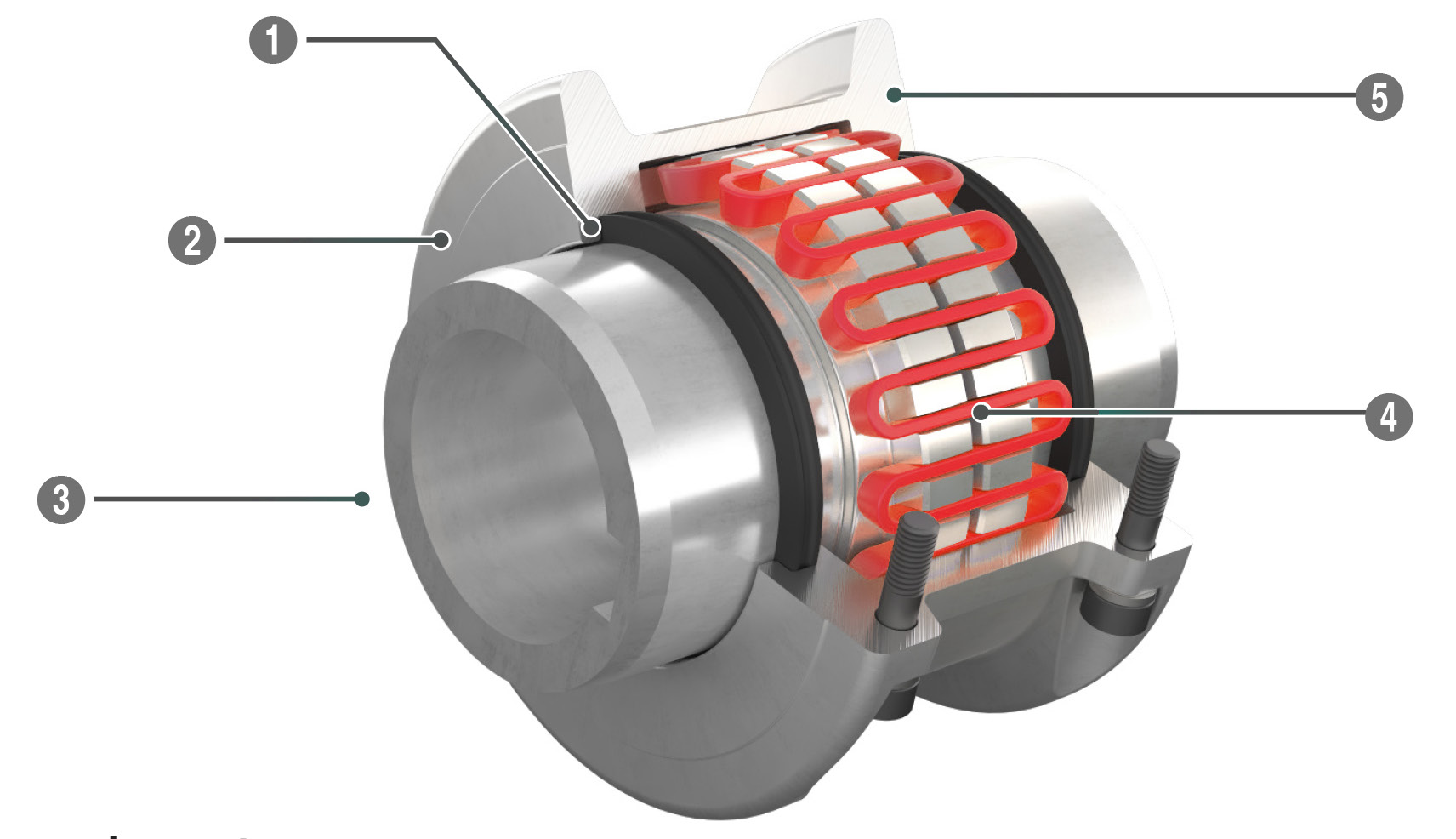

The AEC Grid Couplings are designed to handle significant torque despite their compact size. These all-metal flexible couplings are primarily used to reduce vibration and shock transmission while accommodating both angular and parallel misalignments within their operational limits. In the event of a heavy overload or excessive misalignment, the grid and cover act as a safety mechanism, failing to interrupt torque transmission and protect more expensive drive components from damage.

Compared to other couplings, grid couplings offer simpler installation and repair, and their high reliability leads to reduced and shorter maintenance inspections. ABS Grid Couplings are specifically engineered to provide flexible, efficient power transmission while safeguarding connected equipment from misalignment, shock loads, and vibration. The grid design absorbs impact and reduces vibration, extending the lifespan of both the coupling and the connected machinery.

The flexibility of the grid element accommodates angular, radial, and axial misalignment, all while maintaining high torque transmission. These couplings are ideal for industries such as mining, steel, cement, and sugar, where dependable power transmission and the ability to withstand high loads and operational stresses are crucial. Their robust design ensures long-lasting performance even in harsh industrial environments, ultimately extending the service life of the machinery they support.