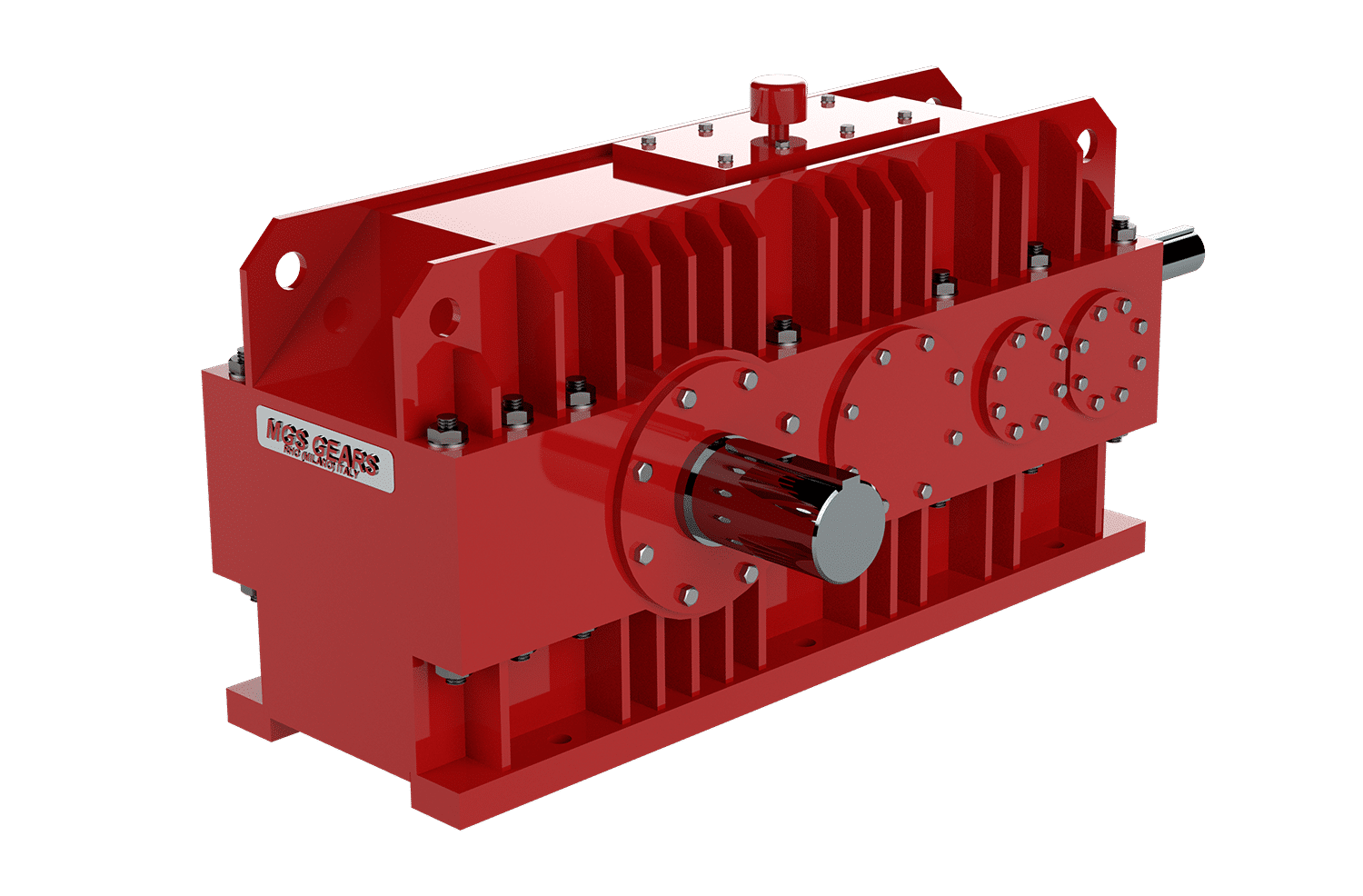

ABS designs and supplies Bevel Helical Gearboxes in a range of sizes, with the ability to customize their features and specifications based on the specific application. These gearboxes are composed of helical-toothed cylindrical gears and two bevel gears. The torsion axis is orthogonal to the motor input axis, allowing for installation in compact spaces. They combine high power density with smooth, quiet operation, making them ideal for systems that require moderately high gear ratios and torque. ABS Bevel Helical Gearboxes ensure consistent and reliable performance, even in the toughest working conditions.

The bevel gear stage allows the input shaft to change direction, while the helical gear stage ensures smooth, efficient power transmission with minimal noise and vibration. Built for durability and high performance, these gearboxes are perfect for industries like mining, steel, cement, and sugar processing, where the ability to handle high torque and loads with mechanical efficiency is essential.