This project exemplifies the way we think of design reliability. Does the furnace environment dictate how long the bearings will last?

ACB Expansion Bearing Assembly Solves Reoccurring Thermal Growth Failure for Galvanizing Lines

See the project on ABS Newsletter pdf

THE BACKGROUND

In the US steel market, the need for specialized coating, painting, and galvanizing production lines have exceeded the limits of most standard bearing products.

These special facilities utilize high heat and acid wash areas that are detrimental to the life of standard rotating components. Atlantic Custom Bearing (ACB) brand can pair the correct tolerance, seal types, and custom housings to perform in these harsh environments.

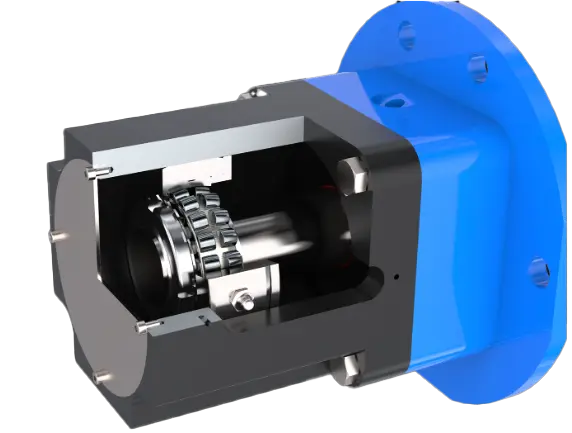

Custom axial-expansion type bearing housing that alleviates the stress on shafts, seals and OEM designs by supporting the bearing through all stages of thermal growth.

SUCCESS STORY

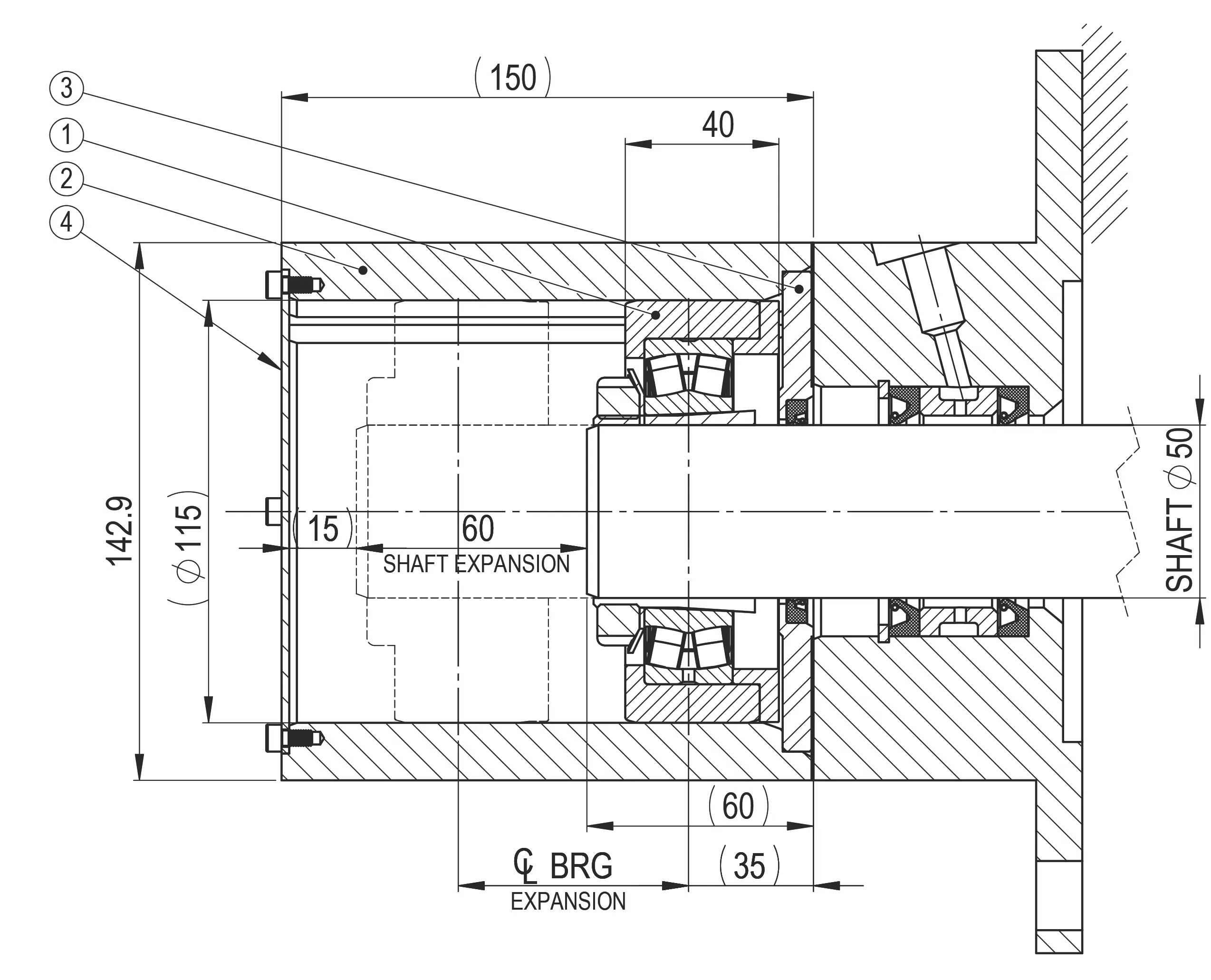

Working closely with the customer’s experienced maintenance teams, ABS Atlantic Bearing addressed the demanding application criteria of 65mm of axial movement of the furnace roll.

THE CASE

During operations, the roll tube furnace reached temperatures of ~860*c, under these conditions the 3600mm roll shaft expands approximately 60mm. Originally, the expansion was displaced through the floating side by pushing the shaft through the loose retaining device on the bearing side. The force required to push through the bearing was causing premature failure of the original cast housings.

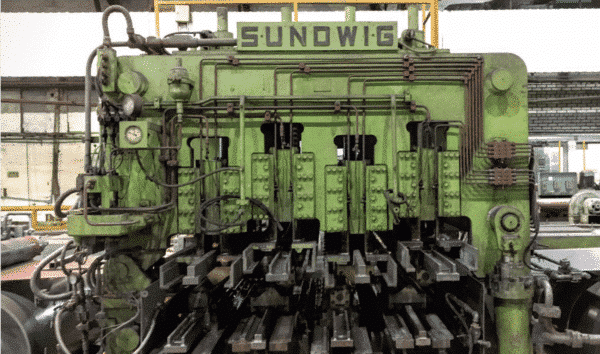

Original design standard 4 bolt flange bearing with the shaft protruding at different lengths because of the different operating parameters.

TECHNICAL CHALLENGE

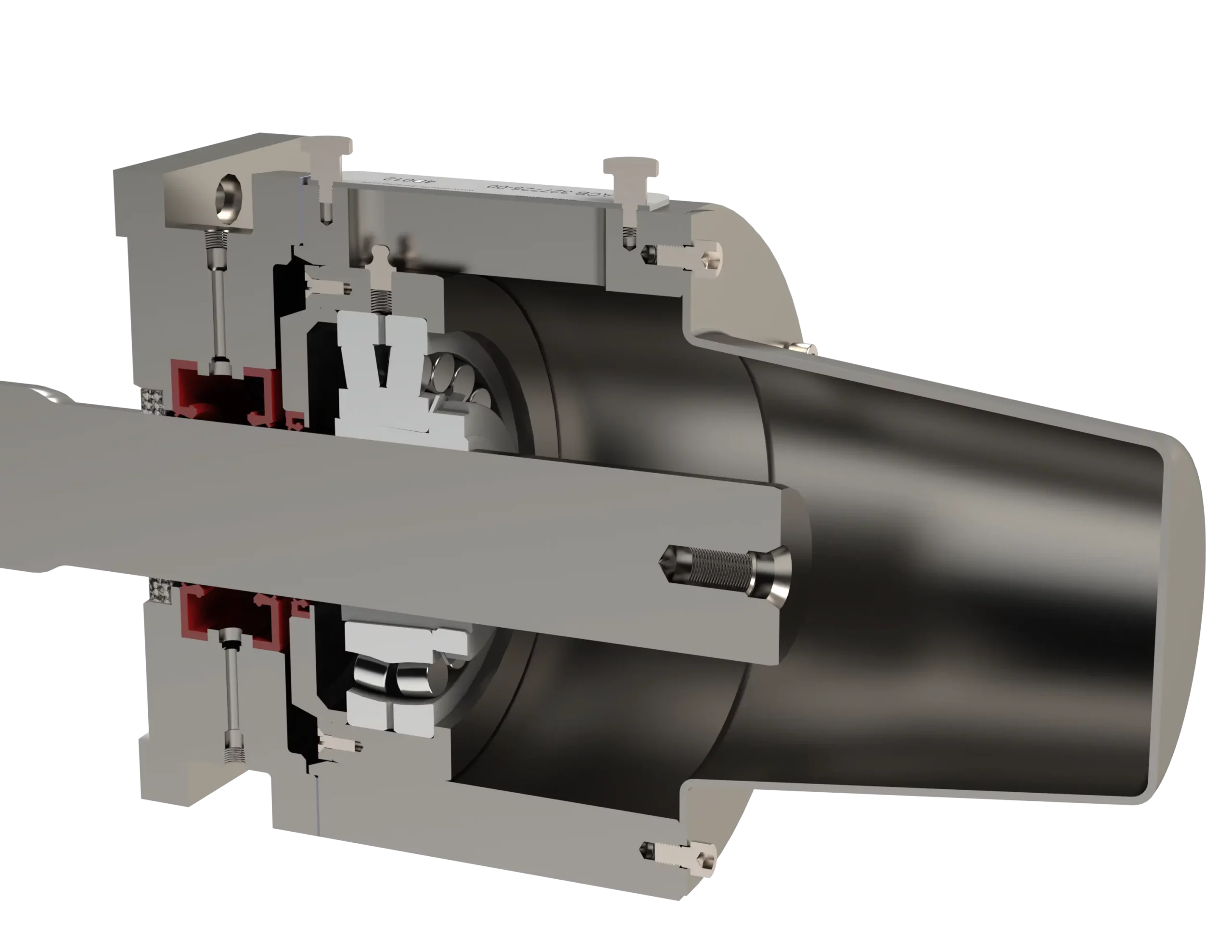

The thermal growth of 60-65mm is difficult to overcome as it greatly exceeds the standard bearing housing’s capabilities. During intense analysis, measurements and data reporting, ABS identified that the best course of action was to support the bearing and allow the free movement of the shaft axially in a custom housing.

The new ACB Bearing (an ABS custom design), brings simplicity to a complicated problem, related to thermal growth in an Easy to install assembly.

ABS TECHNICAL PROPOSAL

Supporting the bearings during different levels of temperature required a tapered bearing adapter that once locked onto the shaft (with a unique floating cartridge keyed design housing) allowed the bearing assembly to not be affected by the axial expansion which plagued the original design.

SCOPE OF WORK

This project shows how ABS utilizes extensive engineering experience to provide our customers solutions to their industrial problems. The tapered cartridge adapter is an attachment used in many heavy industries and can perform in dirty, dusty environments to fix the bearings location on a shaft, even with a limited amount of wear.

FINAL RESULTS

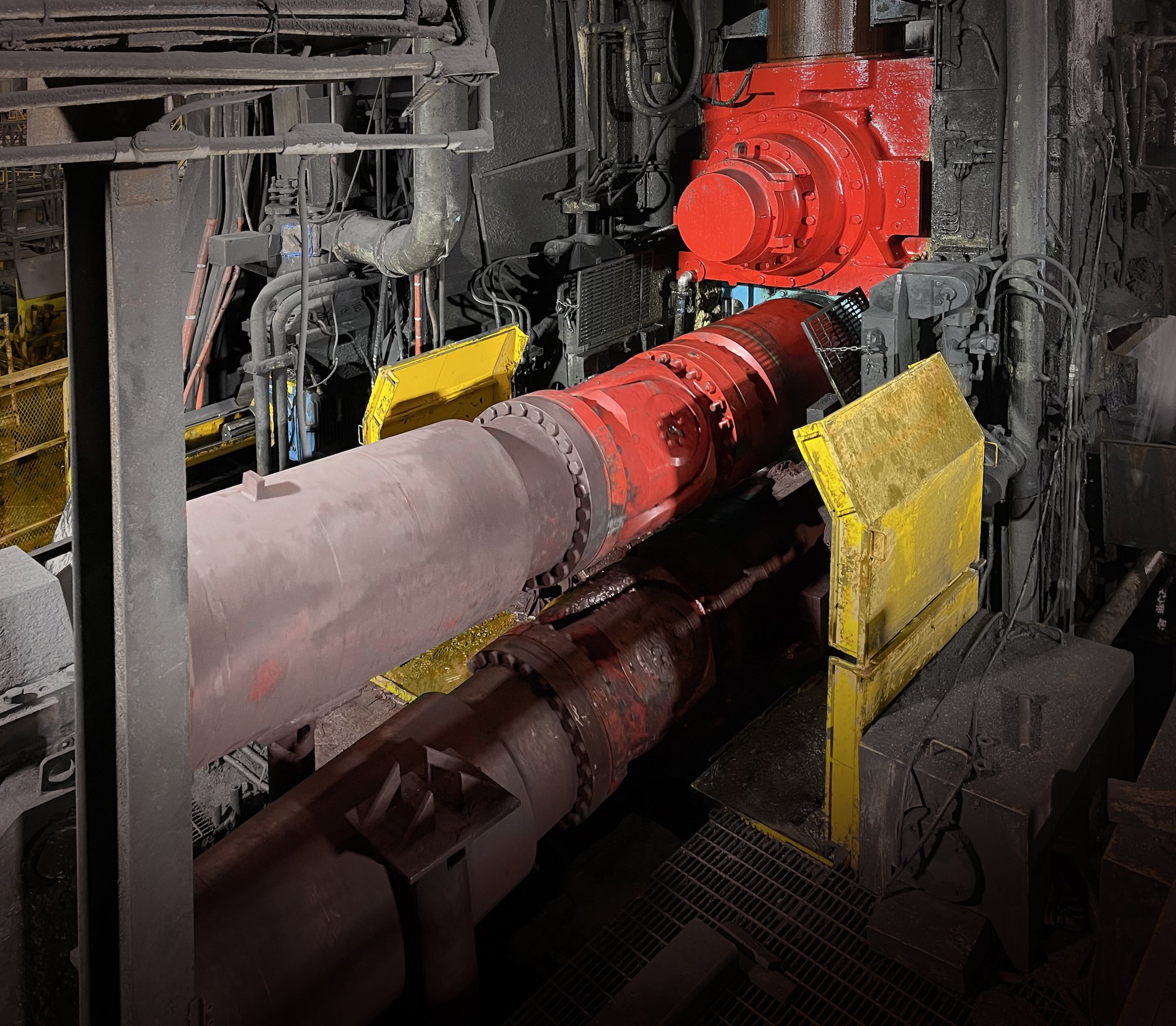

This design has replaced all the floating side bearing housings for one of the premier steel producers’ galvanized line in the U.S. and has been adapted to fit three other production lines at the point of writing this article. These units were installed in early 2022 and are still operating. Exceeding the typical lifespan of the OEM design and improving the reliability at this plant.

ACB expansion bearing assembly installed in the Steel Dynamics galvanizing plant

ABS and its brand ACB Custom Bearings: a sure value for the Steel industry

This project exemplifies the way we think of design reliability. Does the furnace environment dictate how long the bearings will last? We are prepared to assist with an in-depth investigation to improve or enhance your current challenging applications by working with your operation and maintenance teams to provide solutions that increase reliability at your plant.