Discover how Four-Row Cylindrical Roller Bearings optimize efficiency and reliability in long-product steel rolling mills, crucial for producing bars, rods, beams, and more in steel manufacturing.

Four-Row Cylindrical Roller Bearings for long product steel rolling mills

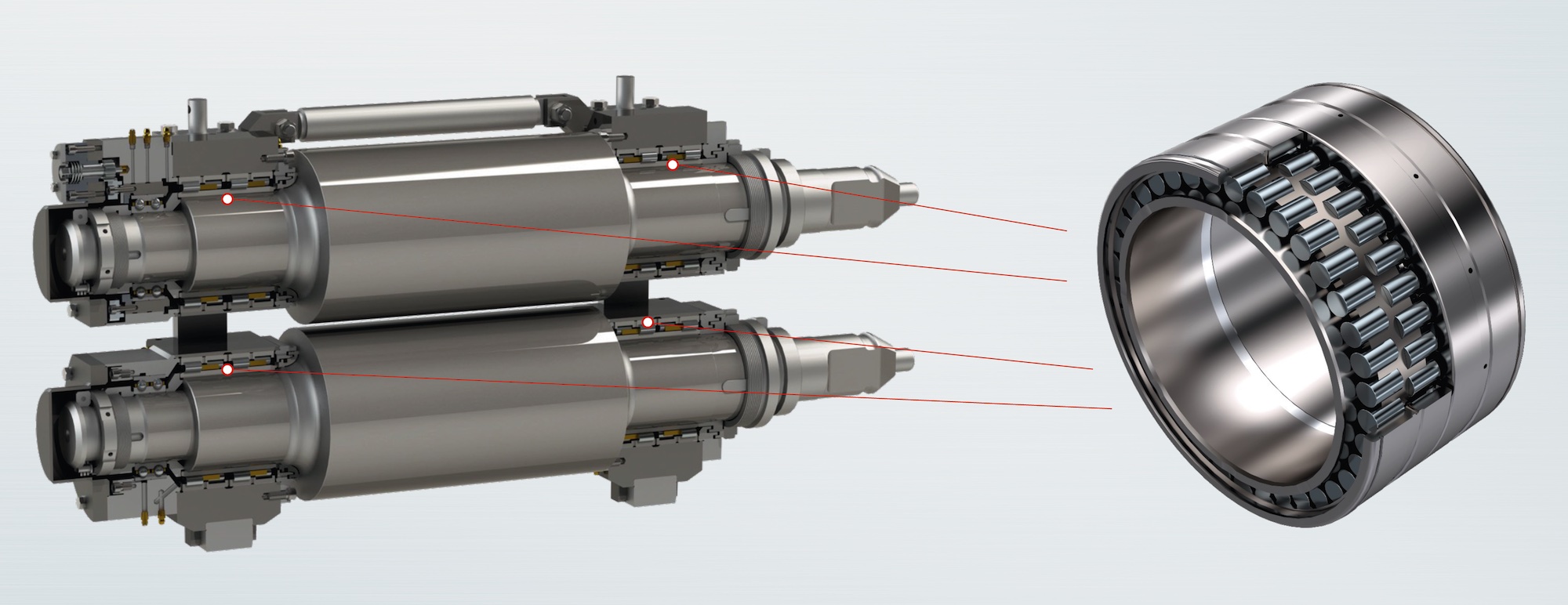

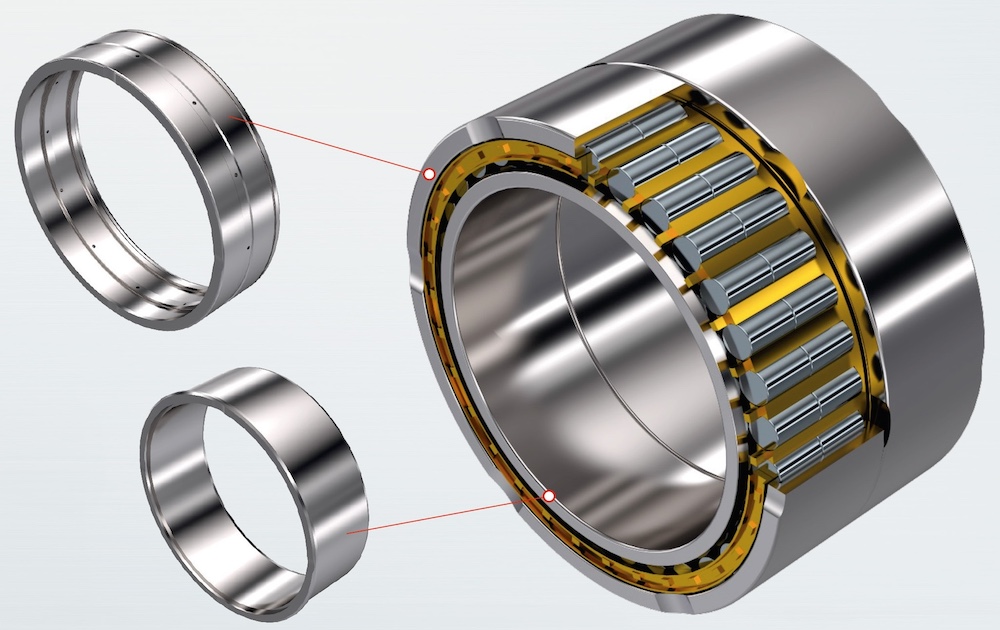

Four-row cylindrical roller bearings for long product rolling mills

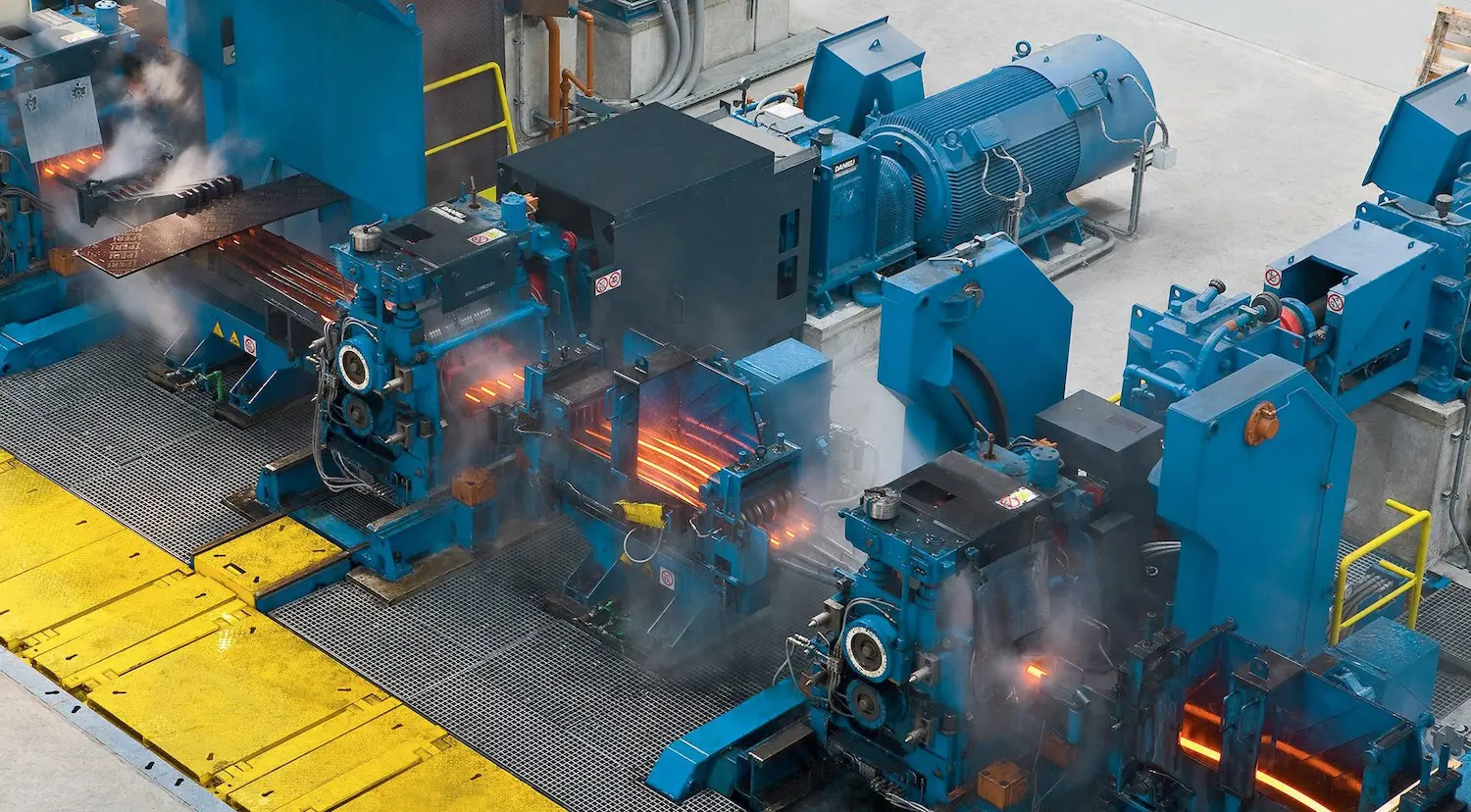

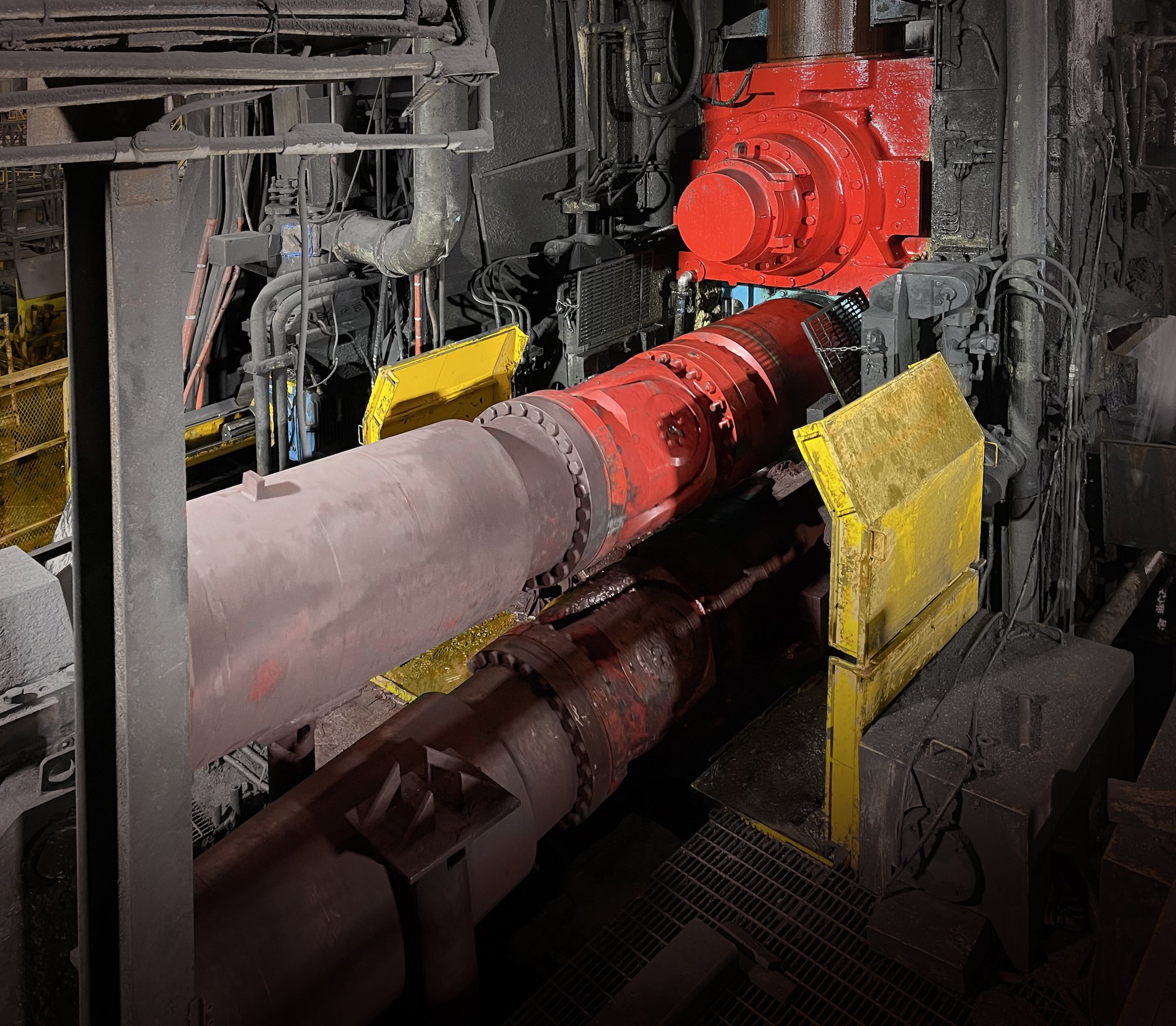

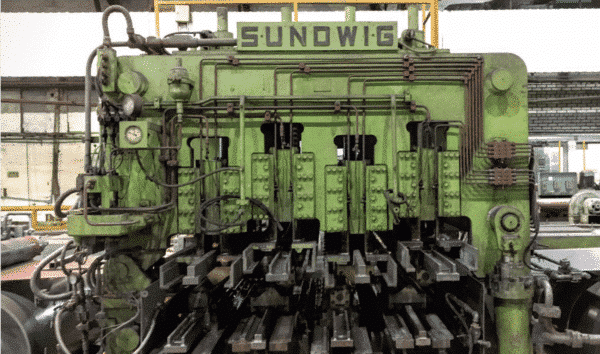

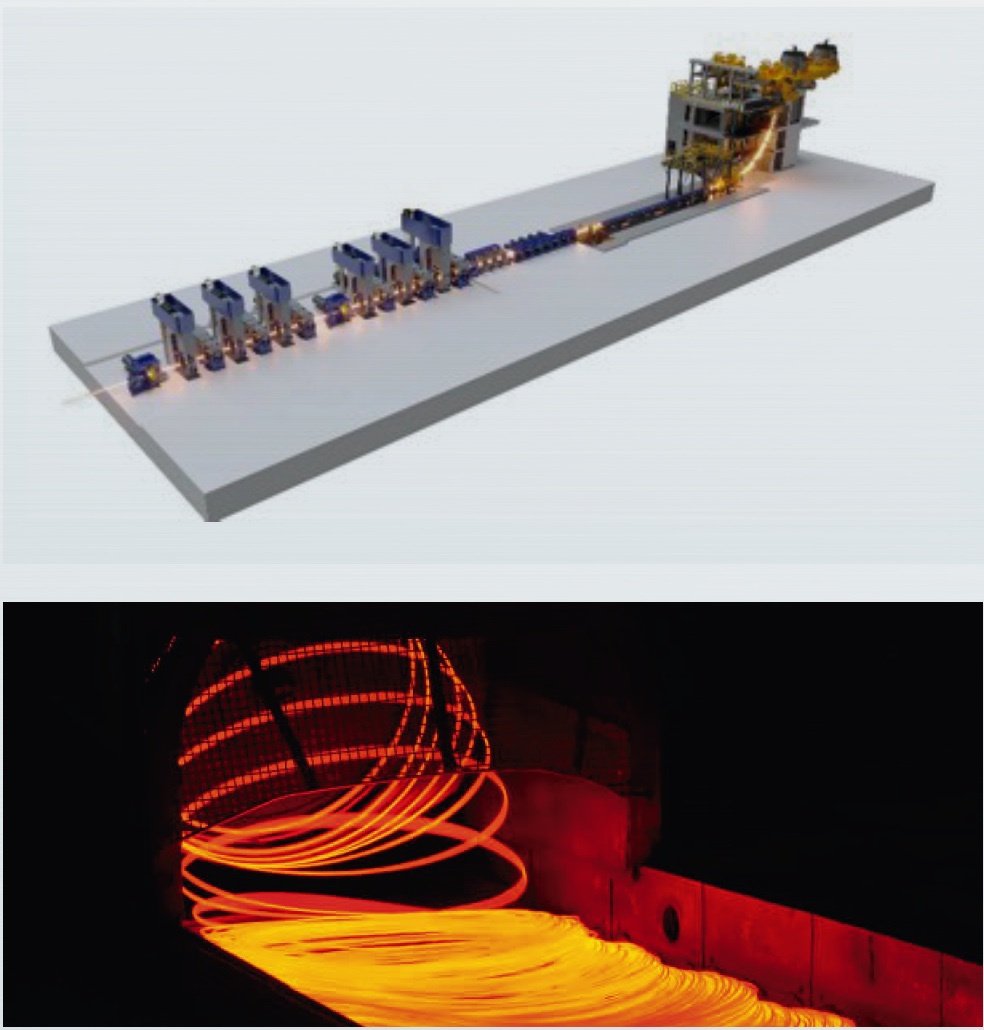

Long-product steel rolling mills are specialized facilities for producing long steel products such as bars, rods, angles, beams, and channels. These mills play a crucial role in steel manufacturing, transforming raw steel into finished products used in construction, infrastructure, and various industrial applications.

Long-product steel rolling mills face several challenges impacting their efficiency, productivity, and overall performance.

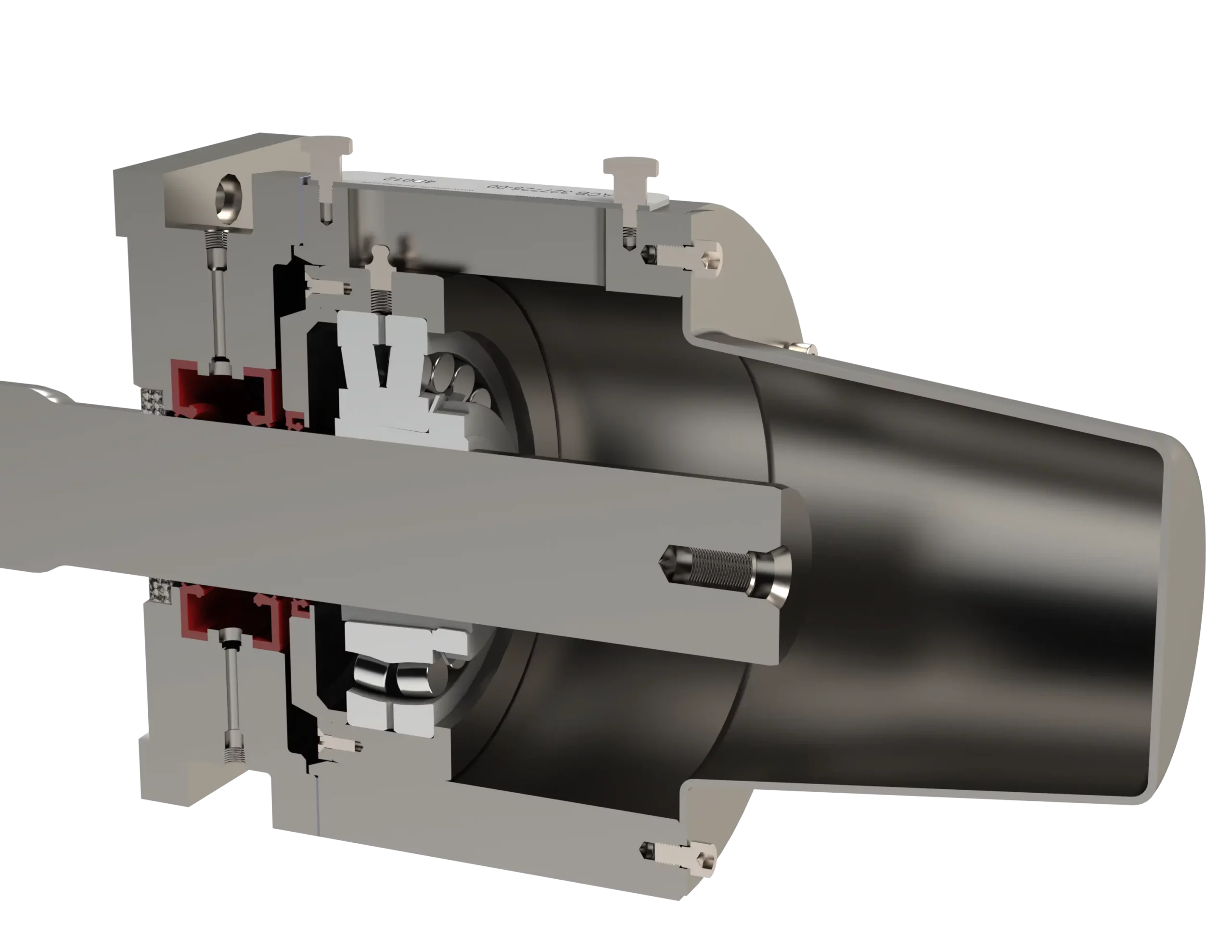

The ACB 4RCRB is designed to mitigate those challenges, improve reliability, and extend service life.

Features and benefits

- Forged steel rings and rollers

- Raceways with super finish

- Rollers with an optimized profile and increased diameter and length for maximum load capacity

- Special rib design to reduce friction and enhance the lubricant film

- Precision class P5

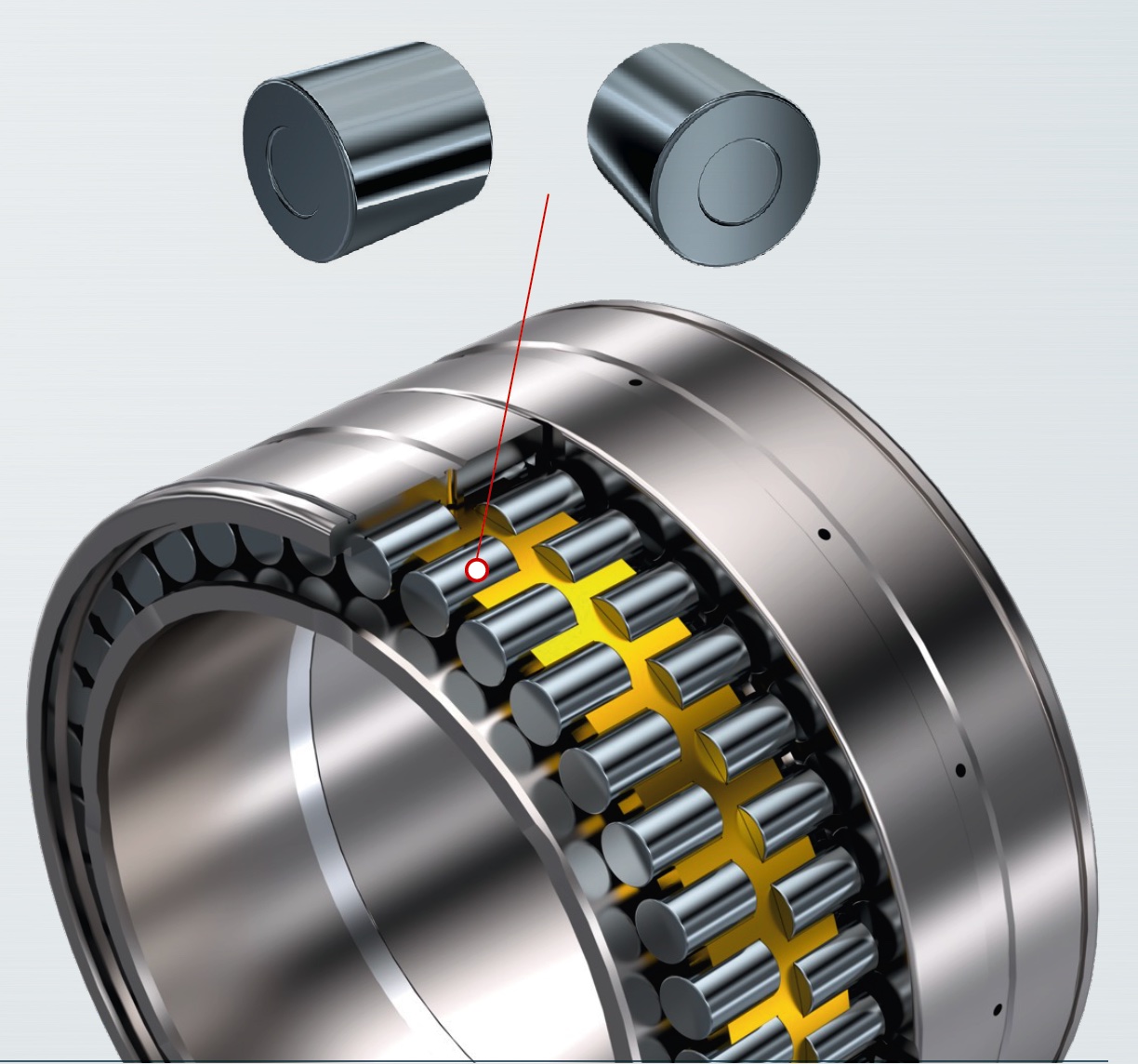

- High-strength brass or hardened steel machined cages

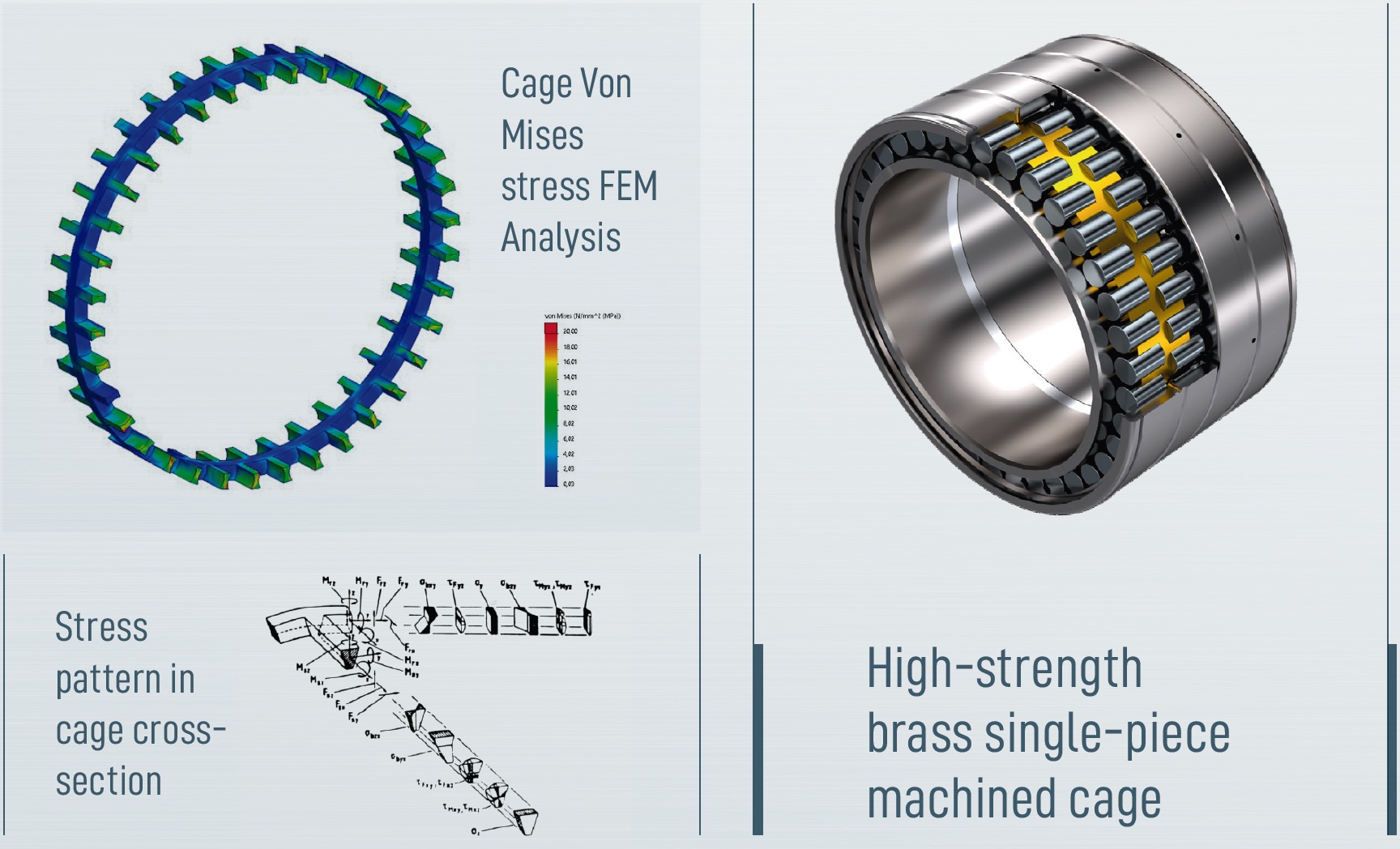

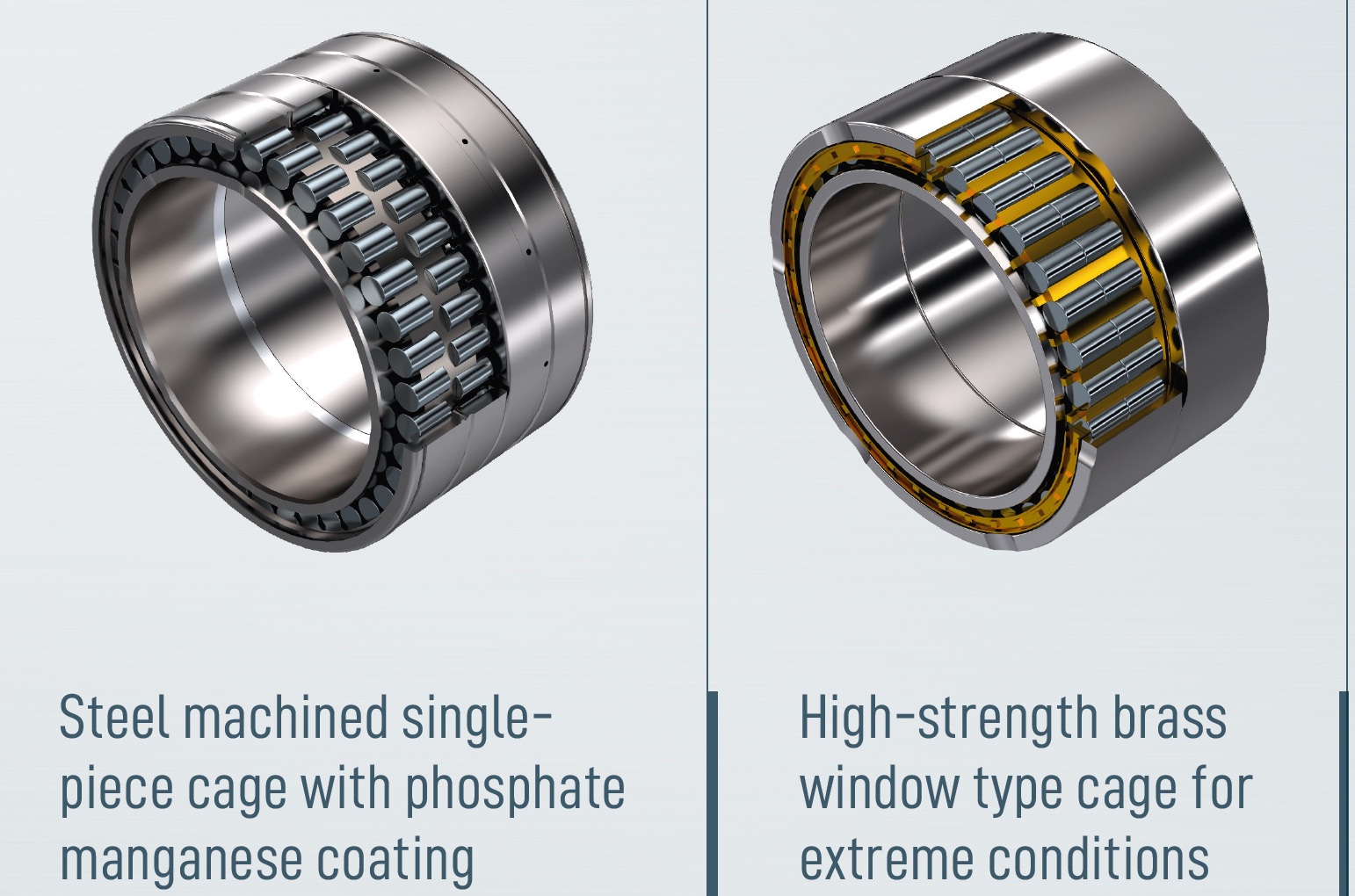

Cages design

High-strength brass (finger and window types) or hardened steel machined cage in single pieces and designed through Finite Elements for maximum quantity and diameter of rollers.

- Cage Von Mises stress FEM Analysis.

- Stress pattern in cage cross-section.

- High-strength brass single-piece machined cage.

- Steel machined single-piece cage with phosphate manganese coating.

- High-strength brass window type cage for extreme conditions.

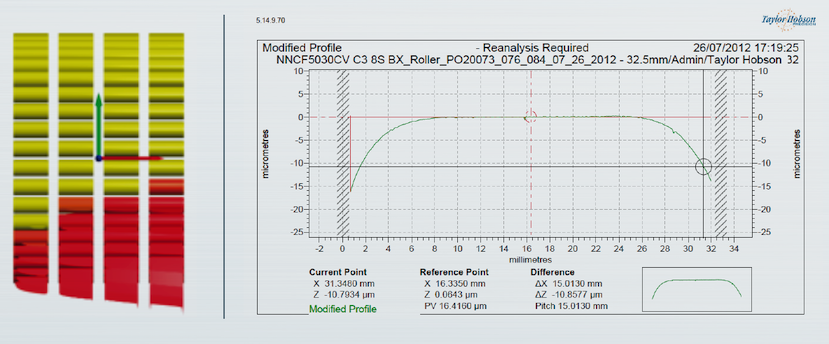

Rollers design

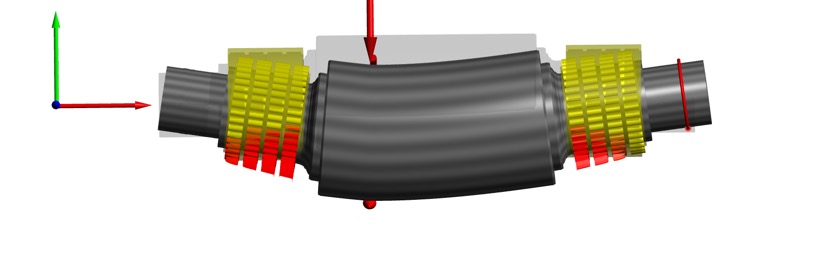

Rings design

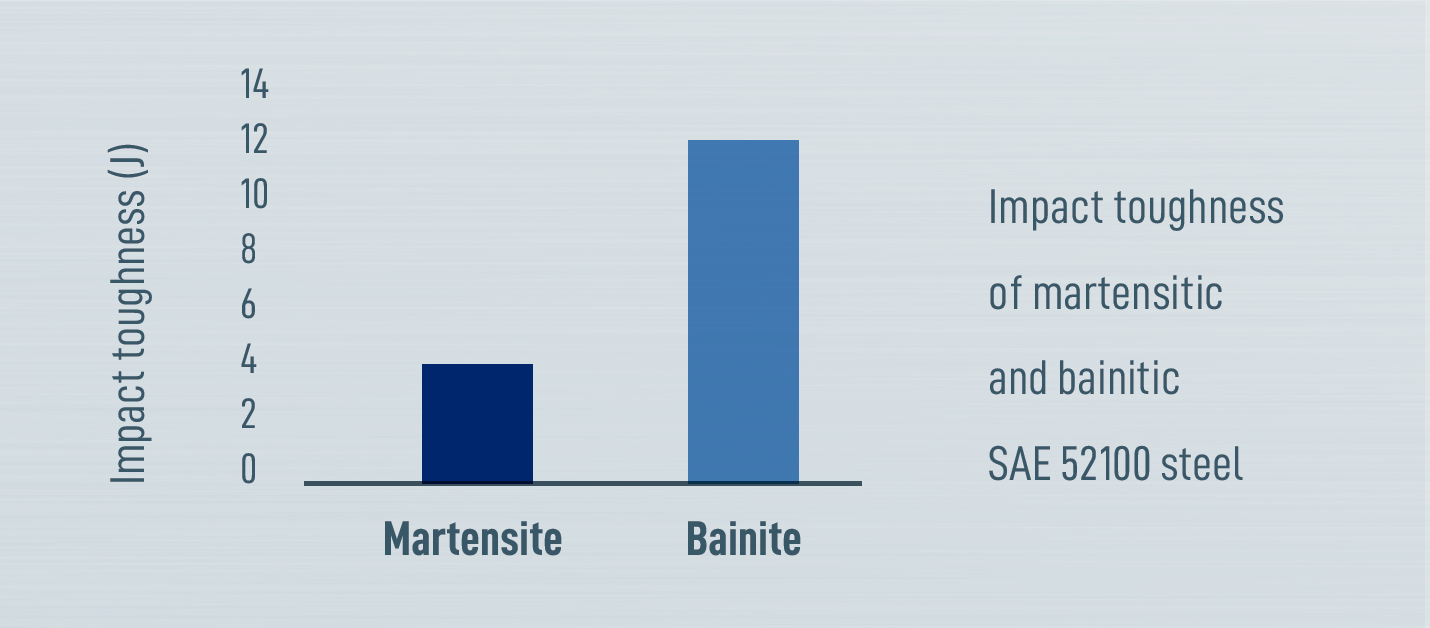

Forge Bainite Hardened inner and outer rings.

- Increased resistance to impact loads

- Increased resistance in contaminated environments

- Lower crack propagation speed

- Higher fatigue resistance Higher fracture toughness

- Slight compression residual stress in the surface zone

- No temper embrittlement

Geometry and micro geometry improvements

- Special design of ribs to reduce friction and favor the formation of the lubricant film.

- Special raceway profile to reduce rollers’ edge stress

- Super finished Raceways

- P5 running precision

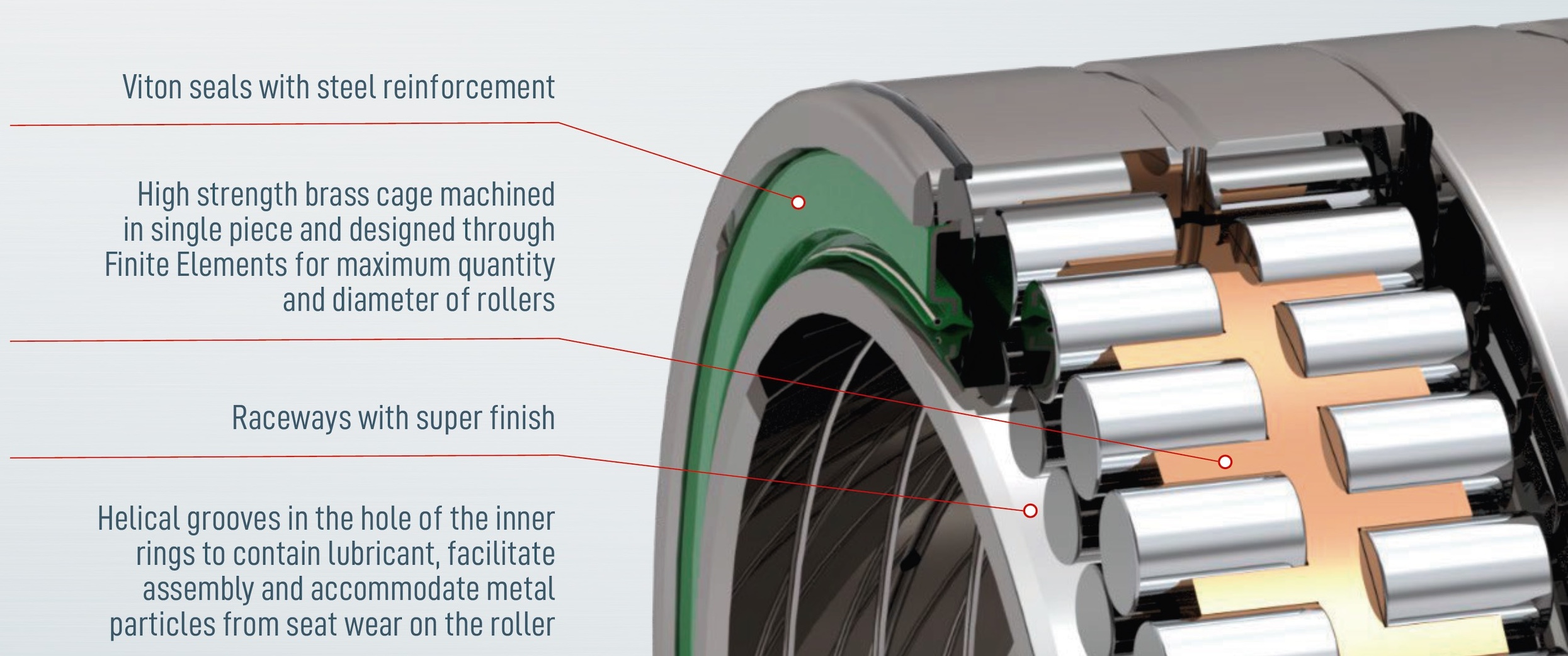

Special design

- Viton seals with steel reinforcement.

- High strength brass cage machined in single piece and designed through Finite Elements for maximum quantity and diameter of rollers.

- Raceways with super finish.

- Helical grooves in the hole of the inner rings to contain lubricant, facilitate assembly and accommodate metal particles from seat wear on the roller.

- Case carburized rings and rollers.